Posté le 10/07/2013 à 23:23

Kitty Upgrade : Fuchs time!

En fait, je suis en train de faire beaucoup de travaux sur Kitty (le petit nom de mon KG) en ce moment, et ça me prend plus de temps que prévu... Et j'attendais d'avoir fini certaines grandes étapes avant de vous poster tout ça ici!

Attendez vous donc à toute une série d'articles "Kitty Upgrade" ; à propos, un grand merci à Bazoom qui m'a fait le dessin en titre de ces posts, et qui représente ce que devrait devenir mon KG à terme! Ouais, je sais, y'a du taf pour en arriver là!

L'une des modifications prévues de longue date est l'installation des Fuchs présentées ici il y a... Pfiou, bientôt 6 ans!

Des véritables Porsche Deep Fuchs d'avant février '71, pas des copies, en 5.5" devant et 6" derrière... Überlike! :

Ça aura pris le temps, mais j'ai fini par les faire polir. Oui, j'ai choisi la voie de la facilité, j'ai pas eu le courage de m'user les doigts 15 heures par jante! (Olive-des-Montagnes, si tu me lis : oui, j'ai honte.

Donc passage en premier chez un décapeur pour virer les couches de peinture. Il n'a d'ailleurs jamais réussi à virer la peinture noire d'origine Porsche, même après 4 passages au bain de décapant! C'était de la bonne came à l'époque!

Ensuite, direction Moriano pour polissage intégral. Note un peu salée, mais travail irréprochable, on croirait qu'elles sont chromées.

Et pour ceux qui me disent "ouh là là ça brille trop c'est bling faut les détailler", ben non, moi elles me plaisent comme ça, elles resteront polies intégralement! (du moins jusqu'au jour où j'en aurai marre de frotter!) Il fallait ensuite décider de la taille des pneus... Choix pas évident, la place est comptée sous les ailes d'un KG.

J'ai donc commencé par écumer les forums VW (F4E, FKG, TheSamba...) pour noter ce que les autres avaient monté. J'ai compilé tout ça dans un fichier Excel, qui pourra servir à ceux qui veulent monter des Fuchs sur un KG : à télécharger ici, vous me remercierez plus tard...

Finalement, je me suis décidé sur des Yokohama 165/65 R15 à l'avant, et du 185/65 R15 à l'arrière, commandés chez 123pneus (livré comme d'hab' en 48H, toujours une bonne adresse!). Les pneus sont montés avec des chambres, c'est pas optimal comme montage, mais bon, pas le choix avec les Deep Fuchs d'époque, elles ont pas les talons pour monter des tubeless...

Après un test rapide, les Fuchs à l'avant passent tout juste avec les pneus en 165/65 R15. Merci le déport intérieur de 42mm sur les Deep 5.5"... Ça frotouille très légèrement quand je braque à fond à gauche, c'est tout. A confirmer en dynamique sur la route, mais j'ai peut-être échappé au rétrécissement du train avant!

En revanche derrière ça ne passe pas du tout, mais ça, je le savais déjà.

J'en profite pour monter des amortisseurs Koni rouges réglables aux 4 coins, tant qu'à travailler la liaison au sol, autant le faire bien. A ce propos, les Konis étaient en ruptures chez les annonceurs VW, mais bien disponibles directement sur le site Koni-Shop, pour moins cher d'ailleurs, et livrés en 24H, imbattable!

La suite... Demain!

Posté le 03/11/2012 à 16:33

200.000 hits Pin-Up

Un pinup so sixties pour fêter les 200.000 visiteurs sur ShamWerks!

Un pinup so sixties pour fêter les 200.000 visiteurs sur ShamWerks! Cette pinup est l'oeuvre du talentueux Will Murai, détails de cette image ici!

Posté le 02/11/2012 à 13:22

Restauration du Crouzet-Valence

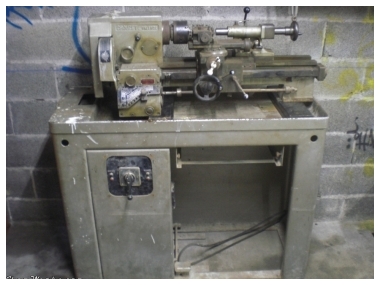

Vous vous souvenez du tour à métaux que j'avais rentré l'année dernière? (cf. post Crouzet-Valence VM125)

Vous vous souvenez du tour à métaux que j'avais rentré l'année dernière? (cf. post Crouzet-Valence VM125)

Ben j'ai commis l'erreur d'en démonter une pièce pour la nettoyer... Puis une seconde... Une troisième... Et bon, j'me suis fait avoir comme un bleu, alors que ce n'était pas du tout une priorité pour moi, j'ai fini par restaurer la bête en entier!

Je dois avouer qu'à force de trainer sur le forum usinages.com (j'y ai un topic sur la resto de mon tour ici), et de voir des machines restaurées à la perfection, la tentation était trop grande!

Peinture

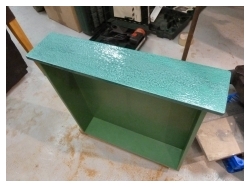

J'ai commencé par peindre le bati, pour y voir plus clair. Dégraissage à l'essence F et éponge Scotch-Brite pour enlever le plus gros de la couche de gras qui couvrait l'ensemble (aidé de WD40 pour décoller la graisse figée sur le bac). Puis lessivage au Saint Marc, rincage, un coup d'alcool à 90° pour virer tout film gras résiduel (le chiffon doit rester blanc)...Et enfin peinture Hammerite vert martelé au pinceau (pas évident à appliquer, mais résultat sympa). Peinture du banc et de la broche : même technique que pour le bâti, essence F/Saint Marc/alcool à 90°/Hammerite... Pas mal de copeaux sont ressortis de dessous le carter de broche lors du nettoyage : de l'aluminium, de l'acier, du laiton, du bronze, du nylon ; il a servi à faire plein de choses différentes mon p'tit tour!

Sur les photos, on voit le banc debout, en équilibre peu stable : c'est le seul moyen de peindre le dessous et l'intérieur du banc. J'ai bien failli prendre l'ensemble sur la g... d'ailleurs, j'en ai eu mal aux cervicales pendant 3 jours...

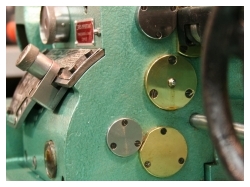

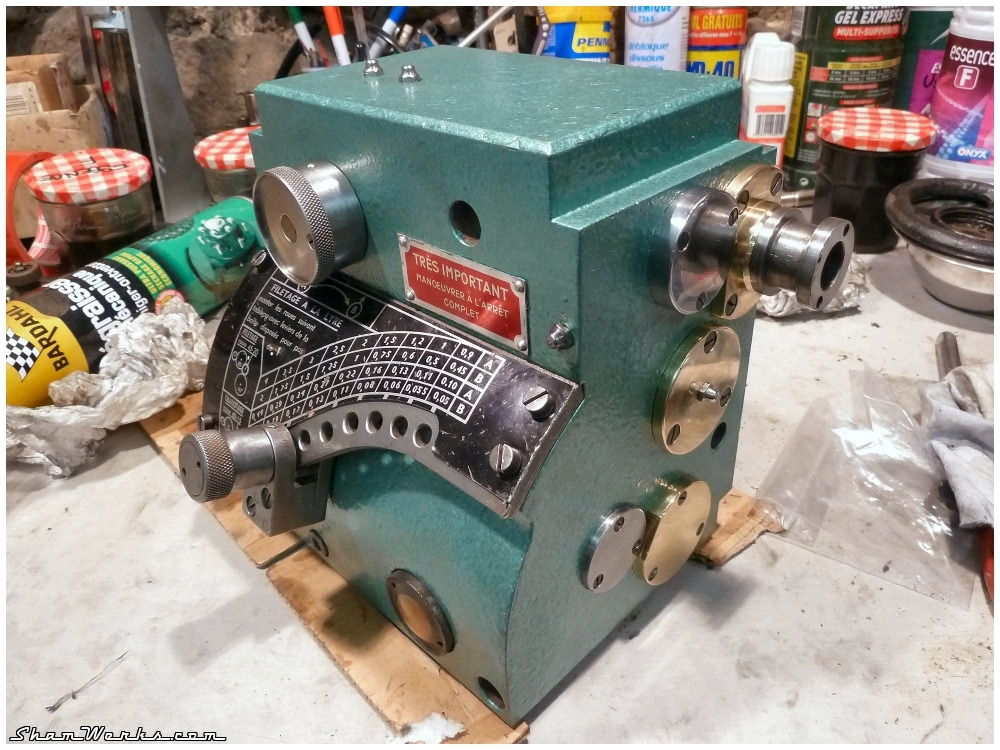

Boite des avances

Je m'attaque ensuite à la boite des avances.Là encore, je ne voulais lui faire qu'un nettoyage global, sans démontage... Et je me suis un peu emballé.

J'avoue avoir eu un instant de doute quand tout a été démonté, tous les engrenages sur mon établi... Mais finalement, avec un peu de patience, de méthode et d'organisation, ça se fait bien.

Certains trouveront "too much" le polissage miroir des paliers bronze, mais j'ai pas pû résister.

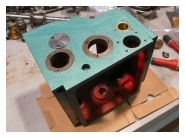

Traînard

Ensuite, c'est le démontage intégral du traînard, jusqu'à la dernière pièce... C'est là qu'il ne faut pas se planter : des dizaines et des dizaines de pièces, des vis de toutes tailles, des goupilles coniques qui ne demandent qu'à être perdues... Il faut être organisé : bacs, pots de confiture et sacs congélation pour rassembler les pièces par sous-ensemble, schémas d'assemblages, photos, tout est bon pour préparer au mieux le remontage et ne rien perdre dans la bataille.Je vous passe le détail du nettoyage de chaque pièce, la méthode employée est systématiquement la même : dégraissage dans un bac à l'essence F, puis brossage à la brosse rotative montée sur perceuse (brosse en plastique bleue, "polissage doux") pour faire partir l'oxydation. Éventuellement, grattage s'il y a des traces de peinture, et un coup de 600 à l'huile sur les traces d'oxydation récalcitrantes.

Et enfin, remontage avec de la graisse/huile neuve, en réglant les jeux : ça, c'est la partie plaisir.

Poupée mobile et mandrin

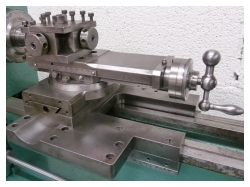

Reste encore la poupée mobile et le mandrin 3 mors à préparer. Pour le mandrin, il faut faire très attention de le remonter comme à l'origine, chaque mors à sa place, les pièces s'étant rodées entre elles.Tiroir

Mon tour était équipé d'un tiroir à l'origine, bien pratique pour garder les outils protégés et à portée de main... Malheureusement, il était perdu depuis longtemps quand j'ai acheté l'engin. Donc, fabrication d'un tiroir de remplacement, en contre-plaqué de 10mm.Un truc au passage pour la finition du contre plaqué : avant de le poncer, l’humidifier avec un spray ou une éponge, et le laisser pauser quelques minutes ; ça soulève le grain du bois et permet un ponçage fin, le rendu final est incomparable (sinon, le grain se serait levé avec la peinture, rendu final rugueux minable!).

Electricité

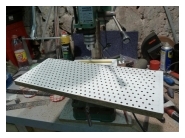

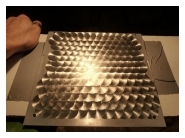

N'ayant pas le triphasé à l'atelier, j'alimente le moteur via un variateur de fréquence (un Altivar 31 de chez Schneider dans mon cas, super produit.).Le moteur d'origine (1,5 kW/2CV, double vitesse) s'avérera en sale état. Je ne sais pas ce que ses anciens propriétaires lui ont fait subir, mais son axe de sortie était dans un état pitoyable, impossible de lui monter sa poulie sans jeu ni faux-rond, l'ensemble se mettait à vibrer à en faire tomber les murs... J'aurais pu envisager une rectification de l'axe, mais comme en plus le moteur "grognait" en charge, j'ai préféré changer l'ensemble moteur + poulie par du neuf. Pour 160€ l'ensemble (moteur de même puissance que celui d'origine : 1,5kW, 1500 tr/mn, poulie 160mm de diamètre) , je préférais avoir l'esprit serein de ce coté là. Pour le panneau de commande, j'avais une idée en tête depuis un moment, je voulais une plaque en aluminium bouchonné. Mais je voulais que le bouchonnage soit vraiment régulier, je me suis donc fabriqué un guide.

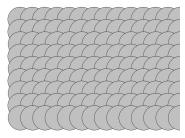

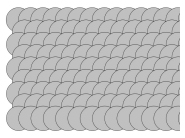

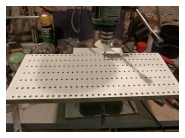

La meule abrasive que j'utilise vient de chez PolirMalin, un peu chère mais elle fait bien son boulot. Les rosaces font 30mm de diamètre, j'ai décidé de les décaler d'un demi rayon par ligne pour obtenir un effet demi-lune plus joli... C'est un poil plus compliqué, mais le rendu est plus sympa, cf. schémas ci-après. C'est là que le guide devient un outil imparable! 403 trous borgnes percés précisément (j'en voyais plus le bout...) dans un bout de mélaminé qui traînait (pas idéal, mais ça marche). Les trous sur chaque ligne sont écartés d'un rayon de rosace (soit 15mm dans mon cas). D'une ligne à l'autre, je décale d'un demi rayon les trous.

Il reste plus qu'à placer les boutons ; j'utilise du scotch de peintre (deux couches) pour protéger l'aluminium pendant que perce. Comme on peut écrire dessus, ça me permet de repérer les endroits à percer directement dessus : Pour l'armoire électrique, j'ai demandé un coup de main extérieur. Je n'avais pas forcément toutes les connaissances pour en faire une aux normes, et en plus le matériel acheté pièce par pièce revient vite cher...

Heureusement, un membre du forum usinages.com propose du matériel d'occasion reconditionné (un grand merci à Emmanuel "Turbo Gros Michel S.A" pour son aide et ses conseils!), et m'a préparé une armoire électrique complète : relais pour le variateur, la pompe et la lumière (je n'utilise pas ces deux derniers pour le moment, mais c'est en préparation), transfo BT 27V pour les commandes, transfo 12V pour l'afficheur de vitesse (en préparation aussi!), arret d'urgence avec temporisateur réglable 2.5s. pour le vario (qui n’apprécierait pas d'être coupé en charge, donc on attend que le moteur freine avant de couper l'alim)... Bref, une vraie armoire électrique, tout comme les grands!

Résultat

Et finalement, le résultat... Un plaisir à utiliser, cette bécane!Pour mémoire, l'état du tour à son arrivée à l'atelier, un petit "avant-après"...

Coût

| Achat du tour : | 200 € |

| Courroies : | 30 € |

| Moteur : | 140 € |

| Poulie moteur : | 20 € |

| Variateur : | 140 € |

| Armoire électrique : | 170€ |

| Divers (peinture, quincaillerie...) : | 100 € |

| Total : | 800€ |

J'm'en suis pas trop mal sorti sur ce coup! Enfin, c'est sans compter les dizaines d'heures de main d'oeuvre, bien sûr...

Mon seul regret : la taille du tour, trop petit pour reprendre un tambour de frein par exemple. Enfin, de toutes façons, un tour plus gros ne serait pas rentré dans mon atelier...

Bon, c'est pas tout ça, j'y retourne, j'ai des copeaux à faire.

Posté le 22/03/2012 à 23:04

Elvira : Réfection du Pied Moulé, épisode 2 : les pièces...

épisode 2 : Les pièces

Acte 2, les pièces :

Le gros problème quand on s'attaque à un pied moulé, c'est bien sûr la disponibilité de pièces...Quoi que la situation se soit un peu améliorée ces dernières années, on trouve maintenant quelques références chez les annonceurs. Par contre c'est de la repro, disponible seulement sous une référence (on peut pas choisir entre Berg/CB/CSP/Scat/etc comme sur un moteur T1 standard), et j'ai parfois des doutes sur la qualité de ce qu'on nous propose.

Tout ça pour dire que ça a été long et pénible, mais j'ai fini par trouver tout ce qu'il me fallait pour remonter le moteur! Faut vraiment être patient avec un pied-moulé... Dans l'atelier comme sur la route!

Au programme :

Pas de préparation old-speed : les pièces sont juste hors de prix, pour des performances limitées, et dès qu'on touche à quelque chose, ça entraine en cascade plein d'autres modifs pour avoir un ensemble cohérent, à la fiabilité discutable.J'avais hésité un temps à investir dans un kit Okrasa repro chez Wolfsburg West, mais tant qu'ils n'auront pas réglé le soucis de fonderie sur les culasses, je resterai d'origine. Un jour peut-être...

Donc, la seule pièce "prépa" sera l'AAC de chez Joe Ruiz, dit "AAC Okrasa", même si Okrasa n'a jamais produit d'arbre à cames pour VW. Il s'agit en fait d'un AAC reprenant les diagrammes de distribution des 356 (rectifiés chez Webcam je crois?), un peu plus pointu, permettant d'exploiter un poil mieux les carburants actuels.

Ensuite, j'optimiserai au mieux le moteur pour être sûr de ne rien perdre des 30cv d'origine :

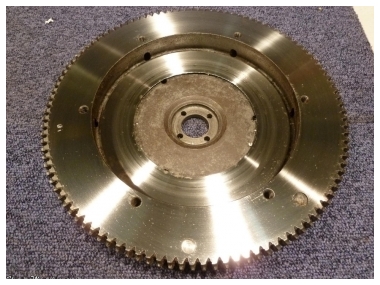

- Vilebrequin, volant moteur et mécanisme d'embrayage équilibrés.

- Bielles et pistons mis au poids.

- Culasses : chambre de combustion et conduits d'échappement polis, conduit d'admission lissé (overkill peut-être sur un 30cv, mais ça peut pas faire de mal de toutes façons), guides contrôlés, soupapes rodées.

Got parts?

Donc voilà le résultat de plusieurs années de recherche de pièces!Enfin, une partie seulement, je vous monterai le reste au fur et à mesure de l'avancement...

A gauche, vilebrequin occasion contrôlé (merci E. Simon), pas du NOS mais nickel, dans les côtes ; au passage avec, un jeu de poussoirs/tiges contrôlés eux aussi. A droite, l'AAC Okrasa Joe Ruiz. Mon volant moteur ayant ramassé, j'ai dû lui trouver un remplaçant : voilà la bête, un peu oxydé, il mérite une rectification ; par contre, les logements des pions sont nickels. Un nettoyage rapide à la paille de fer et il devient plus ou moins présentable. J'en profite pour reprendre au taraud M8 les taraudages de fixation du mécanisme d'embrayage : impossible d'y mettre une vis, entre la rouille et ce qui semble être un reste de pâte frein filet... Bielles VW NOS, coussinets bielles NOS, coussinets vilebrequin NOS, axes de pistons NOS. Je mets au défi tout amateur de vintage de ne pas avoir un début d'érection devant ces photos là!

Ça m'a couté un rein, mais au moins je remonte l’esprit serein. Et puis de toutes façons, j'en ai deux, de reins.

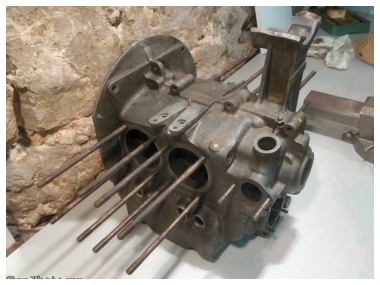

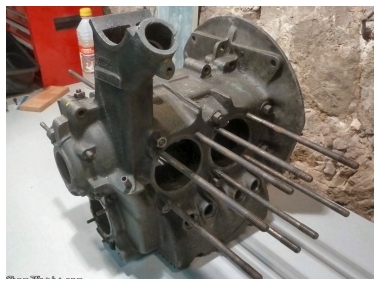

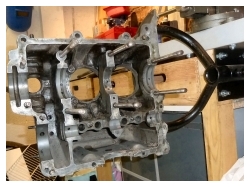

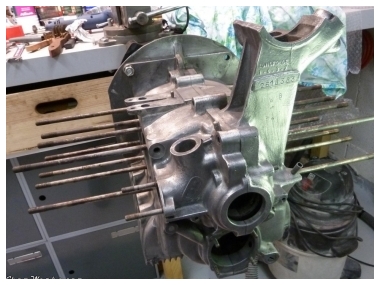

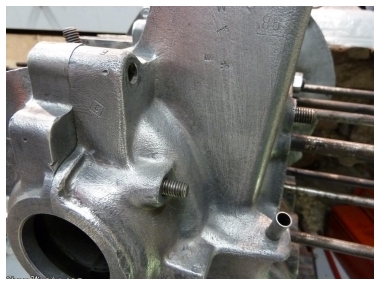

Grand nettoyage :

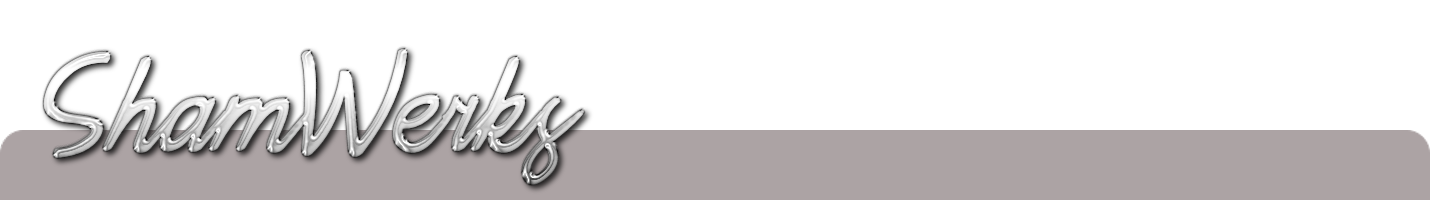

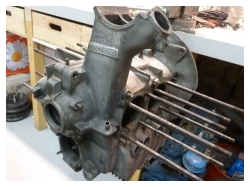

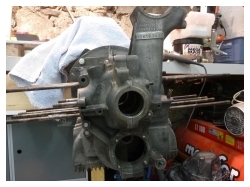

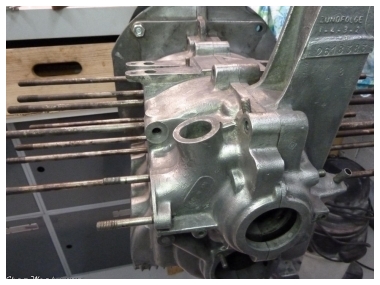

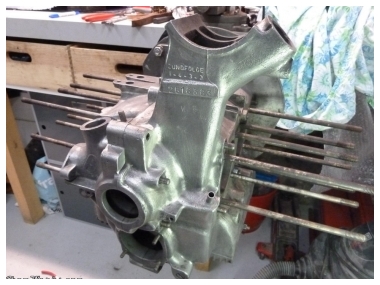

Pour bosser propre, j'ai commencé par nettoyer le carter de fond en combles.Bac, pinceau à dégraisser, brosse à dents, Scotch Brite, WD40 pour commencer, puis dégraissant métaux (produit GSB, nouvelle formulation minable par rapport à l'ancienne...), essence F, Kärcher eau chaude (Elephant Bleu power), et enfin un coup de nettoyant freins pour sécher le métal. Toutes les galeries sont rincées au nettoyant frein, puis soufflette, à plusieurs reprises. Au chapitre des mauvaises nouvelles, le bloc est bien corrodé en dessous. Ça ne remet pas en cause l'étanchéité, ça ira bien comme ça. Le dernier palier d'arbre à cames (pas de coussinets d'AAC sur pied moulé!) coté VM est légèrement piqué. Rien de bien méchant, et l'ancien arbre n'était pas marqué, je laisse comme ça. Finition extérieure : j'avais pensé microbiller l'ensemble, mais j'ai lu que c'est à éviter, il est très difficile de nettoyer ensuite les microbilles dans les galeries et les recoins du bloc. Et si ça commence à se balader dans le circuit d'huile, les effets peuvent être désastreux, je ne prendrai donc pas le risque.

J'ai tenté par contre un coup de brosse rotative nylon montée sur perceuse (modèle bleu, polissage doux du bois, ça se trouve en GSB), et je suis plutôt content du résultat! Ça se ternira un peu avec le temps, mais bon... Une dernière news avant de fermer cet article... Mon vilo/volant moteur/mécanisme d'embrayage reviennent tout juste d'équilibrage chez Slide Performance. Petit coup de pub pour eux au passage, travail sérieux, véritable service de conseil au téléphone, contact sympa... Je repasserai par eux à l'avenir!

Le volant moteur en a profité pour passer en rectification ; comparez avec des photos "avant" juste un peu plus haut, c'est quand même autre chose hein...

Bon! Ça commence sérieusement à sentir le remontage tout ça non?? Restez dans le coin!