Posté le 07/03/2017 à 21:18

Elvira : Réfection du Pied Moulé, épisode 8 : radiateur, tôles et turbine

épisode 8 : radiateur, tôles et turbine

Radiateur d'huile

Je commencer par filer un coup de jeune à mon radiateur d'huile. Je le mets sous pression pour vérifier qu'il est toujours étanche, avec une valve de chambre à air (même méthode que pour ma pipe d'admission). Il tient la pression à 5,5 bars, on est bons.Nettoyage de l'intérieur au nettoyant freins et air comprimé, en secouant bien pour virer tout ce qui aurait pu rester accroché au fond...

Puis sablage léger pour virer la peinture d'origine qui s'écaillait (en bouchant les entrées/sorties d'huile, évidemment), une couche fine de peinture haute température juste pour empêcher la rouille, et re-mise sous pression par acquis de conscience, des fois qu'il n'ait pas supporté le sablage (tout va bien, il tient la pression à 6 bars, #parano).

Je le remonte avec des joints neufs. Next.

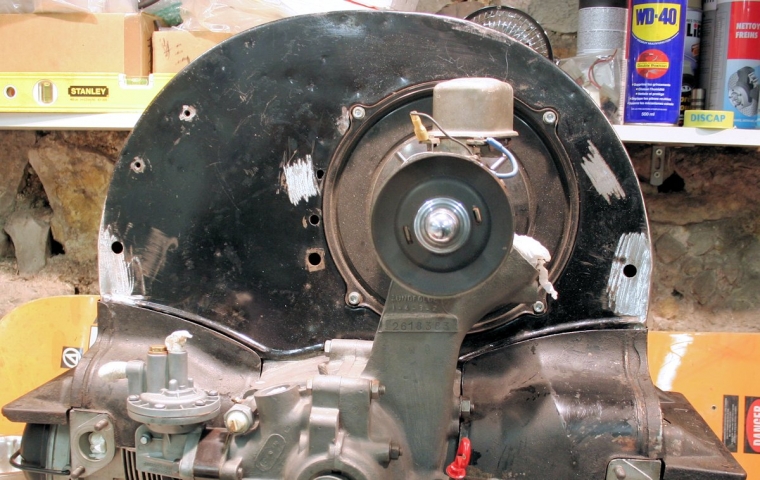

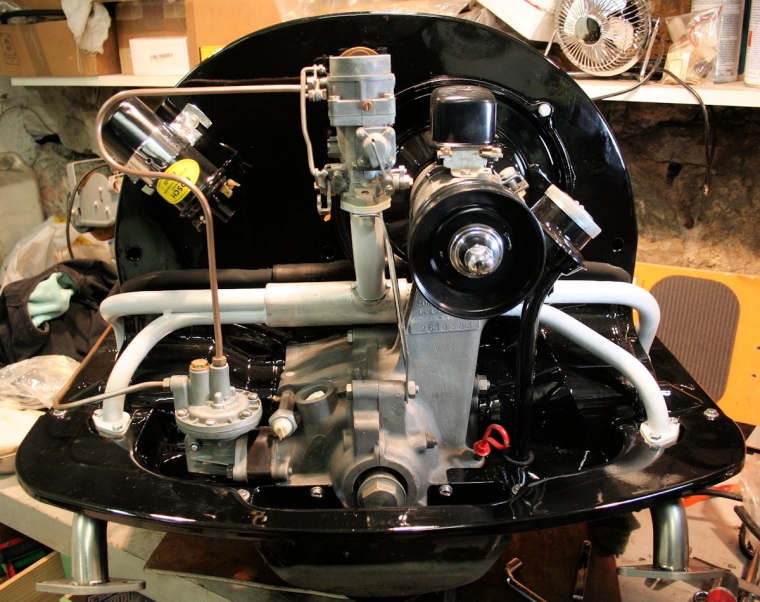

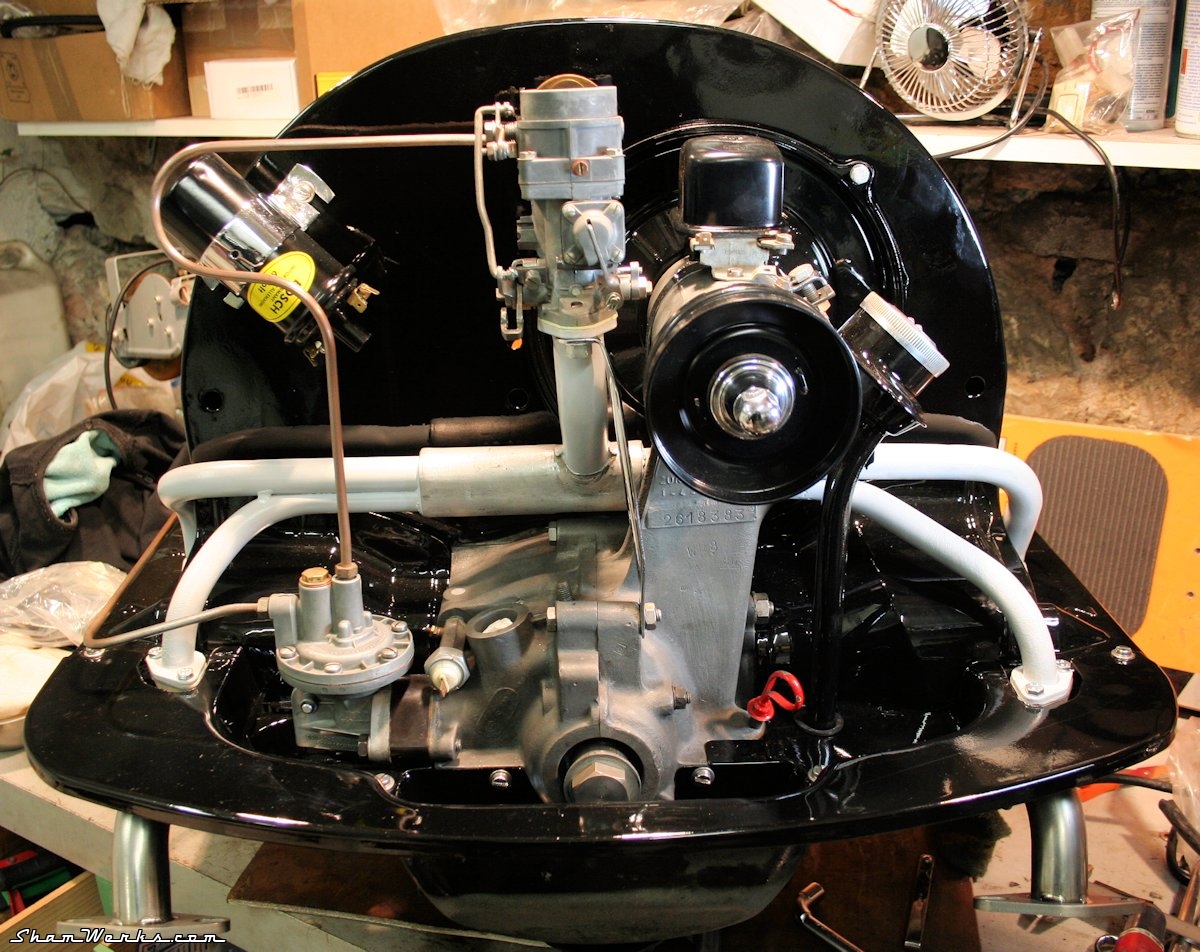

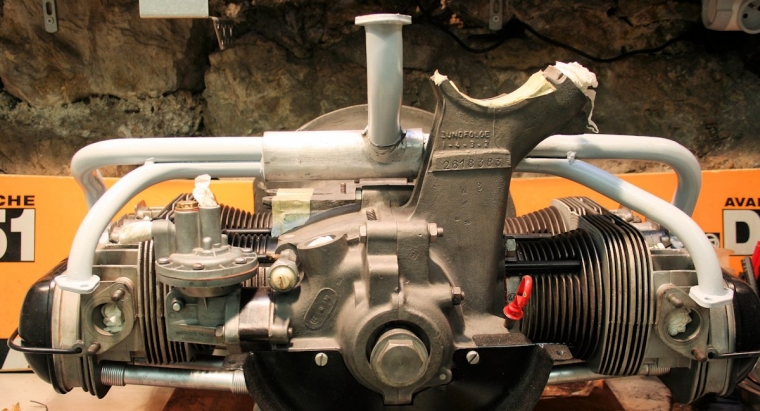

Turbine et tôles moteur

Toujours à cause de la modification des culasses, il faut retoucher aussi les tôles moteurs pour s'adapter à la nouvelle largeur du bloc.Comme je préfère garder mes tôles d'origine intactes, je me suis trouvé un jeu de tôles + turbine d'occasion à modifier. La turbine que je trouve est légèrement différente de celle d'origine, elle n'a pas l'embouti en haut (pour le filtre à air)... Un peu plus ancienne, surement. Comme j'ai en tête de passer en double carburateurs, c'est pas plus mal en fait. Pour les tôles moteur sur cylindres, c'est relativement simple : je sors la Dremel et je leur retire 3.2mm à la base. Circulez, c'est réglé. Pour la turbine, c'est plus tricky : je finis par faire deux découpes triangulaires de chaque coté, qui me permettent de ressouder le bas de la turbine en resserrant ses cotés... Et hop, 6.4mm de largeur en moins.

Enfin, quand je dis "et hop", derrière y'a quand même quelques heures de soudure / meulage hein!

Je voulais tester ce produit depuis un moment, recommandé par un pote... Pas donnée (25€ la bombe chez Vernicispray), mais le résultat n'a RIEN à voir avec une bombe standard! Brillant, tendu.... Joli! Bon, évidemment, utilisée dans un garage poussiéreux comme le mien, on a forcément des limites, mais pour des tôles moteurs, ça me va bien!

Pour utiliser ces bombes de peinture, il faut "percuter" la cartouche contenant le durcisseur par en dessous (cf. photo), avec le "bouton" rouge fourni, puis secouer quelques minutes pour bien mélanger les de. On a alors 6-7 heures pour utiliser le produit, avant que le tout ait durci... Faut donc un peu d'organisation si on veut passer plusieurs couches!

Juste un inconvénient à connaitre : c'est peut-être qu'il faisait trop froid dans mon garage, mais sur la fin de la bombe, ça avait tendance à "moucheter" au lieu de faire un beau brouillard uni (j'avais pourtant fait réchauffer la bombe au dessus d'un radiateur avant, et surveillé que la buse reste propre)... Gaffe, donc.

Le remplissage/reniflard d'huile, la coquille sous la pompe et les tôles demi-lune avant et arrière le moteur prennent tous leur couche de peinture... Je n'avais pas prévu de le faire au départ, mais du coup ils faisaient un peu tache à coté des autres pièces bien shiny.

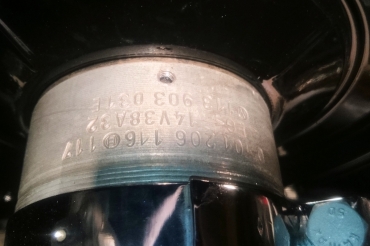

Dynamo

Il y a une douzaine d'années, j'avais converti mon circuit en 12V, en utilisant la très recherchée dynamo 90mm (ref. VW 113903031E, ref. Bosch 0101206116), avec un régulateur Bosch 14V 25A qui-va-bien (ref. Bosch 0190350049).Mais ce régulateur ne tenait que par une seule vis, et de travers, ce qui m'a toujours dérangé (amis obsessionnels compulsifs, bonjour!).

Du coup on prend une grande inspiration, une perceuse à colonne, et on y va. J'ai donc percé à 4.2mm la dynamo (en vérifiant bien, évidemment, que je n'allais pas taper dans un bobinage à l'intérieur!), puis taraudé à 5x80 comme l'autre vis, et hop! Y'a plus qu'à filer un coup de peinture au régulateur, dont j'ai raccourci la patte arrière de 3mm pour pouvoir le monter dans l'alignement du corps de dynamo. C'est quand même mieux!

Bien sûr, comme rien n'est jamais simple, au remontage, serrage de l'hélice à 6mkg, et bim, la rondelle expansible qui casse... Argh. Allez, on en commande une, dispo chez VW Classic parts (ref. 111119135), encore une semaine de perdue... "Patience et longueur de temps font gna gna gna" (bienvenue sur ProverbesAlaCon.com).

...et remontage!

Pour remonter le tout proprement, je commande sur eBay un jeu de vis inox identiques à celles d'origine (les miennes étaient pas belles à voir). Le "joint" cartonné entre la dynamo et son pied est collé au Gasgacinch.Je file un coup de noir satiné sur la bobine (une vrai bleue Bosch), la poulie dynamo et la plaque de pompe à huile (que j'avais oubliée, et qui commençait déjà avoir un des piqûres de rouille).

La bobine reçoit une reproduction de sticker d'époque, et zou... Ca fera quand même moins tache!

Encore un peu d'ajustement et... TADAAAAA!!

Allez, encore un effort et on y est... Si mon épaule veut bien me laisser un peu de répit, ça devrait tourner bientôt!

Posté le 15/02/2017 à 18:08

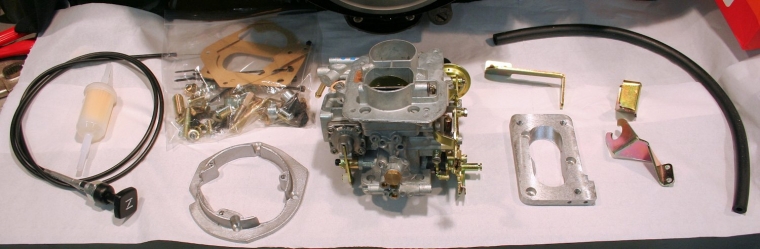

Adieu Pierburg, Bonjour Weber!

Conversion Weber 32/34

Par contre, quand il commence à faire des siennes, on s'en sort plus : c'est plein de capsules à dépression, de dilation, élément de cire, dans lesquels passe le liquide de refroidissement... Bref, une usine à gaz (littéralement!), l'enfer à débugger.

Et justement, le mien s'est mis à déconner, il a mal vécu le swap moteur en avril dernier (j'en parlais déjà à l'époque d'ailleurs).

Il y a une dizaine d'années, j'avais trouvé sur eBay en Allemagne un 2E2 refait à neuf pour pas trop cher, malheureusement le vendeur n'existe plus. Il y a bien un spécialiste en Angleterre (Bromyard) qui propose une rénovation complète, mais à 395 £ + port (plus de 500 €) ça me faisait mal de repartir sur ce nid à problèmes (ceci dit, ils font apparemment du très bon boulot).

Il y a aussi l'option d'acheter une reproduction chinoise neuve du Pierburg 2E2 : on en trouve sur AliExpress pour en gros 100 €. J'avoue que j'ai des doutes sur la qualité du matériel...

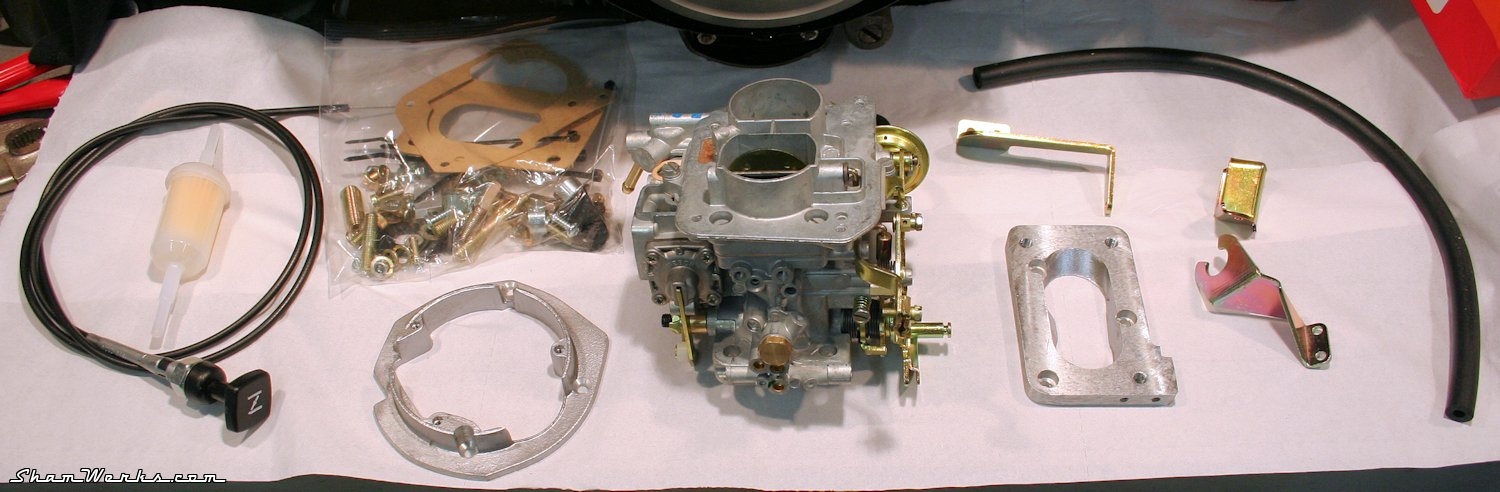

Bref, j'ai fini par craquer, casser la tirelire, et j'ai commandé un kit de conversion Weber DMTL 32/34 chez EuroCarb via eBay, moins cher que chez nos revendeurs nationaux : 324.50 £ port compris (soit 380 €, contre 455 € hors port chez nos annonceurs préférés). C'est un très beau kit, bien pensé, les explications sont claires, c'est du plug'n'play... Même si la traduction en français de la doc laisse parfois un peu à désirer (et les colliers de serrage de durites sont un poil petits, mais là je chipote!).

Et du coup, fini le starter auto au fonctionnement qui tient du vaudou, et retour à un bon vieux starter manuel... Back to basics!

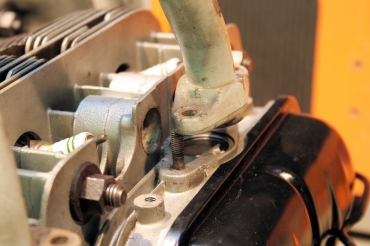

Note au montage : l'attache au bout du cable d’accélérateur venait taper sur la capsule à l'arrière du carburateur, empêchant parfois le retour complet au ralenti... Un coup de tenaille pour raccourcir le biniou et on n'en parle plus (photo du milieu ci-dessous, on voit le point de contact avant modification). Posé le 29/01/2017 et depuis : BONHEUR! Ca démarre au quart de tour, ça accélère franchement, ça ne broute plus à froid, ça ne cale plus pour un oui ou pour un non, j'ai retrouvé le couple en bas... J'aurais du faire ça y'a longtemps tiens!!

Posté le 01/01/2017 à 08:15

Happy New Year 2017

Happy New Year

* 2017 * Bonne Année

* 2017 * Feliz Año Nuevo

* 2017 * Buon Ano

* 2017 * Gutes Neues Jahr

* 2017 *

* 2017 * Bonne Année

* 2017 * Feliz Año Nuevo

* 2017 * Buon Ano

* 2017 * Gutes Neues Jahr

* 2017 *

En revanche 2017 s'annonce quoi qu'il arrive, comme une grande année pleine de changements, pour moi! (edit 20170720 : je vous l'avais dit!

Je vous souhaite à tous une Excellente Année, Santé-Argent-Bonheur-Ah-Mais-Quand-On-A-La-Santé-Ma-Bonne-Dame et tout le tralala.

Bonne route!

Posté le 06/11/2016 à 12:59

Elvira : Réfection du Pied Moulé, épisode 7 : pipe d'admission

épisode 7 : pipe d'admission

N'ayant pas envie de sacrifier ma pipe pied-moulé d'origine, j'en trouve donc une sur LeBonCoin... En avant, découpe à la scie à métaux, et je retire 6.4mm! Je profite de l'accessibilité pour bien décalaminer le tube de réchauffage, qui en avait sérieusement besoin ; c'est plus facile quand c'est ouvert comme ça!

Par contre, je n'ai pas accès à la découpe du coté du premier tube... J'espérais qu'une soudure propre de chaque coté suffirait, mais à la première mise sous pression, ça fuit de partout. Alors je sors la Dremel, et je découpe une fenêtre pour pouvoir aller souder depuis l'intérieur cette jonction. Je ressoude la fenêtre en place, re-mise sous pression, et cette fois c'est nickel! La suite est habituelle : sablage, deux couches d'apprêt antirouille, 3 couches de peinture... Et TADAAAA!! Une pipe d'admission plus courte de 6.4mm! Oui, tout ça pour 6 put*** de millimètres! Ah, il faut l'aimer son RV hein!

Posté le 27/10/2016 à 22:24

ShamWerks a 10 ans!

Il y a 10 ans jour pour jour, je lançais officiellement ShamWerks!

C'était alors une grosse refonte de la version précédente, nommée "Da Sham's Webpage", après 8 ans en ligne ; j'avais déjà une présence online dès 96, mais c'était une simple page sur GeoCities, pas vraiment un site...

En dix ans, c'est un peu plus de 180 articles que j'ai publiés sur ShamWerks. Un rythme plutôt lent comparé à d'autres blogs, mais c'est parce que je préfère avoir du contenu ; et ça, ben ça prend du temps!

D'ailleurs, la longueur moyenne de mes articles n'a fait qu'augmenter, pour atteindre le triple de ce qu'elle était en 2008!

Récemment, ShamWerks a évolué pour s'adapter aux dernières évolutions : le site est maintenant accessible depuis les téléphones et tablettes! Son logo, lui aussi, a pris un petit coup de jeune... Du coup, p'tit cadeau pour fêter ça :

Merci pour votre fidélité, vos messages, votre aide... Bonne route à tous, à bientôt!

Posté le 25/10/2016 à 00:30

Elvira : Réfection du Pied Moulé, épisode 6 : Géométrie distribution

épisode 6 : Géométrie distribution

Ben oui, comme je suis rentré de 3.2mm dans chaque culasse, le moteur est 6.4mm moins large...

Bref, il va falloir (entre autres...) raccourcir les tiges de poussoirs!

Sur les moteurs pied-moulé, à la différence des T1 plus récents, les poussoirs et la tige ne font qu'un...

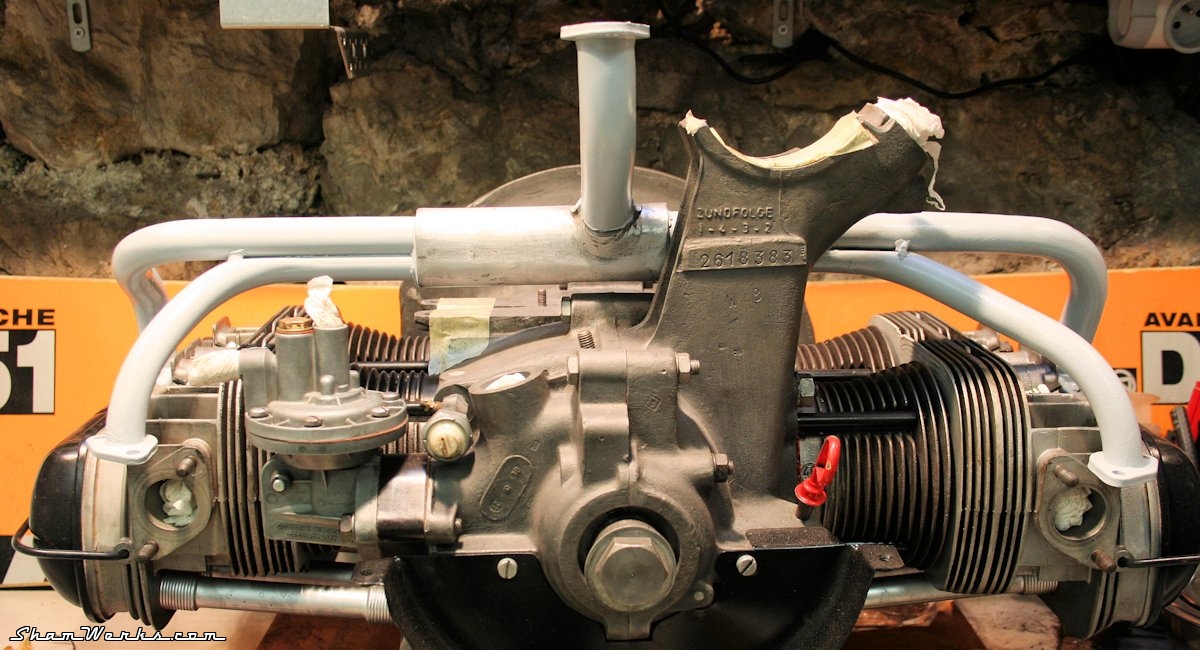

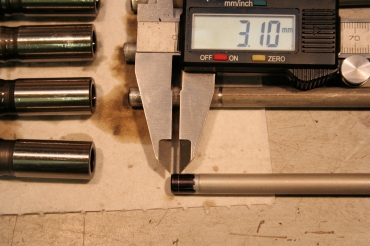

Je commence donc par me bricoler une tige réglable pour définir la bonne longueur : une vieille tige poussoir coupée en deux, un bout de tige filetée, une paire d'écrous, et roules. Ensuite, je sors alors le comparateur pour mesurer la levée totale ; j'obtiens 7,76mm à la soupape, ce qui est raccord avec ce que j'avais obtenu avec mon banc de mesure d'arbre à cames (article à lire ici). Je me place alors à mi-levée (soit 3,88mm) : il faut que dans cette position, la vis de pression du culbuteur soit bien dans l'axe de la soupape.

Note: les plus pointus d'entre-vous pourraient argumenter que ce n'est pas à mi-levée qu'il faudrait faire ça, mais à l'angle auquel on a la plus grande accélération linéaire de la soupape, car c'est là qu'on a le plus de contraintes. Mécaniquement, c'est juste... Mais bon, c'est qu'un pied moul' avec des ressorts façon chewing gum, pas un 2,4L avec des double ressorts en adamantium qui prend 8000 tours, la technique de la mi-levée sera une approximation bien suffisante!

Bref, je j'ajuste la longueur de ma tige réglable pour avoir mon culbu dans la bonne position... Essai, dépose de la rampe, réglage de la tige, et on recommence... En trois essais, je tombe sur la bonne longueur : 299,2mm, alors que les tiges d'origine font 302,3mm... J'ai donc 3,1mm à retirer de mes tiges : ça se tient, puisque j'avais descendu mes fûts dans les culasses de 3,2mm d'un coté et de 3,15 de l'autre, je suis dans les clous. Pour les raccourcir, il faut d'abord retirer la partie "poussoir" : ça se fait bien en mettant la tige dans un étau (entre 2 pièces de bois pour ne pas la marquer), et en tapant avec un jet en bronze sur le poussoir. Les tiges sont raccourcies au tour, montées dans une pince tirée W20 8mm (meilleur centrage qu'au mandrin). Je retire aussi un petit dixième sur le diamètre, sur une longueur de 12mm, sinon la tige ne rentre plus sur le poussoir (j'en ai plié 5 en essayant...). Ils devaient avoir une machine en usine qui permettait de les maintenir sur toute la longueur, pour emmancher en force le poussoir tout en évitant à la tige de flamber.

Pour vérifier que la tige n'est pas pliée une fois le poussoir : on la remet dans le bloc et on la fait tourner du bout des doigts : si elle reste bien centrée dans le tube enveloppe, c'est qu'elle est droite! Evidemment, il ne faut pas la rentrer à fond, sinon le méplat sur le poussoir empêche de la faire tourner.

Intermède historique

Les tiges de pied-moulés peuvent contenir une baguette en bois (du hêtre) : la seule pièce en bois dans une coccinelle! (si on ne compte pas les capotes des cabriolets...)Mes tiges en sont dépourvues ; j'en ai une autre (cadeau d'Eric SIMON) qui elle, contient bien ce morceau de bois. Le rôle de cette baguette n'a jamais clairement été établi...

(Edit 20161103 : Oops, j'avais oublié d'ajouter les photos!) J'ai lu plusieurs théories :

- Pour faire monter l'huile aux culbuteurs par capillarité : pas crédible, pas de pression, pas de débit, et l'huile retomberait de toutes façons dans la tige. Je n'y crois pas un instant.

- Effet de pompe créé par la baguette en bougeant dans la tige de haut en bas... Pas crédible non plus à mes yeux, on a une pompe qui pousse derrière, je vois pas comment ça fonctionnerait.

- Pour amortir les vibrations et réduire le bruit moteur en absorbant certaines harmoniques : admettons, pourquoi pas.

- Pour limiter le volume d'huile dans la tige. Ca limite le poids de celle-ci, et ainsi allège la distribution. En plus au démarrage, moins de volume à remplir dans le circuit, et donc mise en pression plus rapide. Pourquoi pas, ça se tient. Le débit est de toutes façons limité par le diamètre du trou sur le poussoir d'un coté, et celui dans la tête coté culbu de l'autre : on n'a pas besoin que la tige soit entièrement pleine d'huile.

C'est tout pour cette fois, la suite bientôt!

Posté le 26/09/2016 à 20:14

Krapo Bleu : Recaro et Tringlerie de boite

Recaro & Tringlerie

Ma Golf est une 10 Millionen/Champ, et cette édition limitée avait plusieurs options très spécifiques, dont le tissus utilisé pour sa sellerie, un bleu à rayures que l'on ne trouve sur aucun autre modèle (cf. photo ci-après, tirée de la brochure d'époque).

Enfin, ça, c'est ce que je croyais depuis presque 20 ans, jusqu'à il y a 2 ans environ...

Quand j'ai découvert par hasard qu'en 1989, une série limitée de Jetta (la série "GLI Helios"), produites exclusivement pour le marché américain à 1500 exemplaires, avaient elles aussi reçu ce même tissus.

A la différence que sur ces Jetta, les sièges avant sont les très sexy baquets Recaro!

Evidemment, je me suis mis à en chercher une paire, mais ils sont quasiment introuvables, et quand une petite annonce apparaît, c'est forcément aux US, avec des frais de port astronomiques.

Etant d'un naturel têtu, j'ai continué à chercher, sans trop d'espoir, pendant presque 2 ans...

Jusqu'à ce qu'en Mars 2016, une petite annonce sur eBay en Angleterre en propose une paire, qui plus est à quelques kilomètres du domicile d'un membre de ma belle-famille! God Save the Queen!

Je vous passe les détails de l'organisation pour rapatrier les sièges jusqu'ici, mais ça y est, ils sont là, et ils sont encore plus beaux que je ne l'espérais!

(oui, bon, OK, autant d’énergie dépensée pour une paire de sièges, j'ai clairement un problème, j'irai me faire soigner à l'occasion, je peux continuer maintenant?!) La différence en images entre les sièges "Sport" d'origine et la version Recaro : Mais comment ces pièces, réservées au marché US, ont pu atterrir en Europe?

En fait, il y a une dizaine d'année, un militaire américain sur une base aérienne au Royaume Uni, a décidé d'importer sa Jetta Helios... Il l'a finalement revendue sur place, mais un accident a conduit la caisse à être vendue en pièces. Les sièges ont alors été achetés, et ont passé les 9 années suivantes stockés, avant que leur propriétaire ne s'en sépare. Ils ont d'ailleurs été attaqués par des rongeurs pendant cette période, mais ont été réparés à la perfection par un sellier, avec un skaï identique à l'origine.

La suite, vous la connaissez...

Autant dire que ces sièges en Europe, ca ne court pas les rues!! (même si j'ai trouvé un Allemand qui lui aussi en a installé dans sa 10 Millionen)

Il me fallait encore des rails pour les installer... J'ai trouvé mon bonheur en Pologne (eBay est une drogue dure), avec un set de rails de G60 complet avec réglage d'inclinaison électrique (too much?

Pas évident à installer par contre, c'est très tendu! Ma solution a finalement été d'attraper le crochet à tirer avec une pince étau, puis d'utiliser un gros serre-joint pour tirer la pince vers le bord du siège. Et.... TADAAAAAAAA!

Il me restera encore à poser un fusible 20 ampères et une longueur de câble pour le réglage électrique des sièges, mais j'en profite déjà bien comme ça! Dear Martin, thank you so much for your help securing the Glorious Seats!

Bonus : Tringlerie de Boite

Pour continuer dans l'esprit d'amélioration/fiabilisation du Krapo, je décide de lui faire une grosse update de sa tringlerie de boite.D'origine, les guides et renvois en plastique s'usent, cassent (j'ai bien dû les changer 3 ou 4 fois déjà...), et on se retrouve avec un jeu au levier de genre 10 centimètres, qu'on soit en prise ou au point mort! La voiture reste utilisable si on la connait bien, mais c'est inexploitable en conduite appuyée. C'est un bon anti-vol ceci dit, quelqu'un qui ne connait pas la caisse a toutes les difficultés du monde à passer une vitesse!

Je commande donc un kit "Smartshift 2" chez USRallyTeam, qui remplace toutes les articulations de la tringlerie par des rotules Unibal, et les guides par des paliers en Delrin (POM). Radical!

L'installation du kit, le 30/01/16, ne se fait pas sans douleur (littéralement), puisqu'en coupant l'une des rotules d'origine à la disqueuse, je fais un faux mouvement et m'attaque le pouce gauche avec le disque à tronçonner : coupé jusqu’à l'os (bien marqué), tendon sectionné, nerfs embarqués... #LeSamediSoirCestBlocOpératoire

Enfin bon, ça m'a valu une nuit à l’hôpital, mais le kit est installé, et je n'ai plus du tout de jeu dans mon levier, guidage nickel, l'agrément de conduite n'a plus rien à voir!

Bref, sur les photos ci-dessous, vous pouvez voir les vilaines rotules en plastique d'origine, qui prennent du jeu et cassent, et la "boule" qui s'use et prend du jeu aussi...

Deuxième photo, le kit d'USRallyTeam : c'est pas la même histoire hein!

Je vous épargne aussi la photo de mon pouce en mode "Frankenstein" après l'opération...

Bref, pas du plug'n'play, mais une amélioration notable au final.