Posté le 21/11/2022 à 23:19

Elvira : Réfection du Pied Moulé, épisode 11 : repose moteur

épisode 11 : Repose moteur

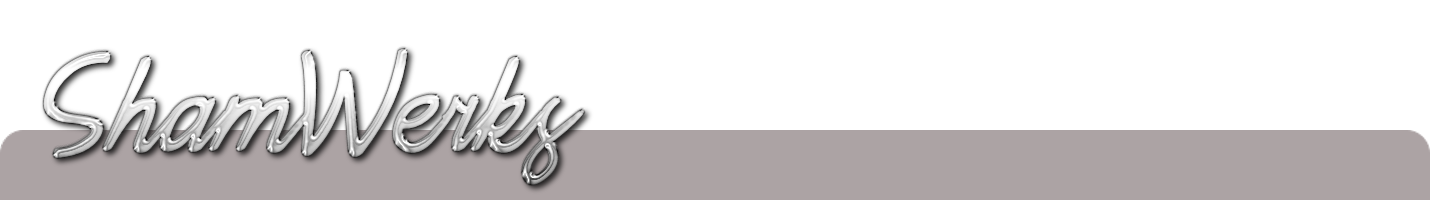

Baie moteur

Comme il était hors de question de remonter mon beau moteur tout propre dans une baie moteur dégueulasse, j'ai décidé de virer l'insonorisant carton d'origine, qui était tout déformé - et je préfère le look de la tôle dans le compartiment moteur, quitte à perdre l'isolation phonique qu'il procure. Je vire aussi les deux petits coussins cachés dans les cornes de la carrosserie, un vrai nid à rouille. Ensuite grosse séance à l'acétone pour virer les restes de colle (il y allaient pas de main morte sur la colle chez VW), et meulage des petits picots soudés qui maintiennent le carton d'origine... Masquage de tout ce petit monde, et protection de l'atelier... Qui ne suffira pas au final, j'avais sous-estimé jusqu'où l'overspray pouvait aller, mon sol en gardera des marques... Puis mise en apprêt, ponçage léger, et peinture de la baie moteur à la bombe polyuréthane bi-composant de chez VerniciSpray - pub gratuite, j'aime bien leurs produits (dèja utilisés sur les toles moteur). Hey, c'est plutôt propre comme résultat, non? (avec les joints de tour moteur neufs aussi passage...)Préparation montage

Tant que le moteur était déposé, j'en ai profité pour changer les supports de boîte, y compris celui du nez de boite spécifique à l'année modèle '60 (référence VW 111301265C). Je remplace aussi le joint spi de l'arbre de boite de vitesses, modèle spécifique aux split-case (référence VW 111307113C) : il a une collerette parce que son logement n'a pas de portée au fond sur lequel il s'appuie. J'avais toujours le joint d'origine en place, qui au bout de 60 ans avait bien durci et méritait d'être remplacé...Attention à l'installation, du fait de l'absence de portée sur laquelle le joint viendrait buter une fois en place, on peut taper un peu trop fort, l'enfoncer trop loin, et il est alors difficile de ressortir le joint sans l'abîmer (ne me demandez pas comment je sais ça

Le ressort de rappel du levier de la fourchette d'embrayage ayant cassé (il allait bien avant, étrange quand même...), je le change aussi. Attention, modèle spécifique splitcase là aussi, référence VW 111141723A.

J'ai remplacé aussi toutes les durites d'essence, le filtre à essence (installé sous le réservoir), et le robinet sous le réservoir qui a toujours fuit depuis que j'ai cette caisse. Je suis un peu parano de l'incendie, je poserai sûrement un Blazecut bientôt aussi...

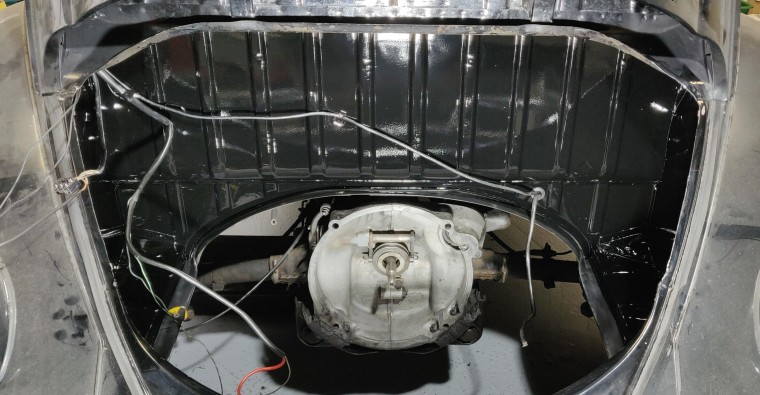

Je pose un faisceau d'allumage neuf (Bosch), en remontant des repros des supports caoutchouc spécifiques aux modèles 59-61 (référence VW 113905451), avec une touche de vaseline pour qu'ils se mettent en place sans trop forcer sur la turbine. Je garde pour le moment l'allumeur d'origine, à remplacer à l'occasion par un 010...

Remontage moteur

Bon... Ben cette fois on a fait le tour je crois, le moteur est prêt à retourner dans la caisse. Ce que je fais tout seul en moins de 15mn, l'avantage des petits moteurs d'origine...Du coup je n'ai pas (trop) galéré pour le monter, pour une fois que quelque chose se passe comme prévu!

Avec un peu d'ajustement je remonte les toles sous moteur et les boites de chauffage 'cf. leur restauration sur mon post précédent), et je connecte tout ça à l'échappement.

Premier démarrage

Finalement, 13 Avril 2021 (oui, oui, je sais, je suis à la bourre sur la publication de mes articles!), tout est prêt pour le premier démarrage... J'en menais pas large je dois avouer.Réglage statique de l'allumage à 7.5°, puis réglage des culbuteurs, amorçage de la pompe essence et de la ligne avec une pompe à vide qui sert normalement à purger les freins (ça marche très bien pour ça aussi)... J'ai ensuite mis le circuit d'huile sous pression en débranchant la bobine d'allumage puis en faisant tourner le démarreur jusqu'à ce que le témoin de pression s'éteigne (ce qui prend 20/30 secondes). Ça permet d'avoir tout le circuit rempli pour le premier démarrage et évite que le vilo tourne à sec sur les coussinets...

Après, ben... Un coup de Start Pilot, une grande inspiration, et... Ouf, c'était une grosse étape ça! Un réglage carbu à affiner, un coup de lampe stroboscopique, plus 2 ou 3 bricoles, et on reprend la route!

Bon, la première sortie s'est malheureusement finie sur dépanneuse à cause d'un renvoi de pompe à essence, cf. edit du 2021/10/22 sur le post dédié... Mais depuis ça roule nickel!

Posté le 08/11/2022 à 17:20

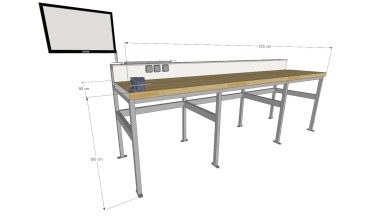

Atelier : établi 2.0

Bon, il est bien mon "Atelier 2.0", mais sans un "établi 2.0" pour aller avec, difficile de travailler dans de bonnes conditions. J'ai bricolé jusque-là sur le dessus de ma servante, mais il est temps de passer la seconde...

Bon, il est bien mon "Atelier 2.0", mais sans un "établi 2.0" pour aller avec, difficile de travailler dans de bonnes conditions. J'ai bricolé jusque-là sur le dessus de ma servante, mais il est temps de passer la seconde...

J'en avais déjà fait un pour l'ancien garage : vous pouvez retrouver sa construction ici ; il avait ensuite pris un coup de peinture...

Mais la grosse différence, c'est qu'il était alors fixé aux murs de chaque côté : dans le nouvel atelier je ne peux pas faire pareil car les cloisons sont en bac acier, non structurel. Ici, le seul point de fixation est sur la charpente de l'atelier dans l'angle à droite... et au sol. La structure de l'établi doit donc être très rigide, pour que ça ne bouge pas dans tous les sens et cogne contre la cloison du fond si je dois secouer quelque chose dans l'étau...

Du coup cette fois-ci, ça ne sera pas en bois, mais en acier : la structure sera faite de tube carré 40x40 et rectangulaire 80x40 (#overkill). Il me restait du 40x40 de la construction de l'atelier, je suis donc parti sur la même dimension pour optimiser le stock... Je sais, j'ai une certaine tendance à surdimensionner ; la sousdimensiophobie, ce fléau.

Design / Repérage / Marquage

Allez, on y va : si ce n'est pas la première fois que vous venez ici, vous connaissez la boutique, ma première étape c'est Sketchup pour trouver la meilleure configuration : Le résultat fait 3m15 de long pour 80cm de profondeur, et 1m de haut parce que je suis grand et que je me casse le dos sur une hauteur standard...Initialement j'avais prévu de mettre ma servante en dessous, mais ça devenait alors trop haut, surtout que j'ai une mezzanine de stockage à 2m10 au-dessus. Du coup je mettrai plutôt la servante sur le côté, avec un morceau de plan de travail dessus, pour avoir un établi complet en "L". Y'a plus qu’à!

Je commence par marquer précisément, au sol et sur les murs, l'emplacement de l'établi, ça me servira de référence par la suite (le niveau laser est l'outil magique pour ça). Le sol n'étant pas parfaitement plat, chacun des 8 pieds peut avoir une taille légèrement différente de ses petits copains, je les monterai donc tous "en place" pour être sûr d'avoir un dessus plan et une structure d'équerre. Raison supplémentaire de faire tout en place : l'angle des murs dans ce coin n'est pas exactement à 90° à cause d'un mur mitoyen avec le voisin, ce montant de l'établi ne sera pas d'équerre avec le mur du fond comme les autres, faudra adapter...

Structure

Je commande ensuite l'acier chez un spécialiste, Durcomfer à Villeneuve Loubet : les barres de 6m en 40x40 à 36€TTC, alors qu'on est à 15/20€ du mètre en GSB, y'a pas photo. Livraison le lendemain de la commande (30€ la livraison), bon accueil, pas cher, je repasserai par eux à l'avenir.Pour la fixation au sol, chaque pied est soudé sur une semelle en plat d'acier de 40x8mm d'épaisseur. Chaque semelle est alors boulonnée au sol avec deux chevilles acier Ø12mm pour vis M8 70mm de long. Au total 16 tirants, ça ne devrait pas bouger. #overkill4ever

Bon, ceci dit, on ne va pas se mentir hein, mes soudures ne me feront jamais gagner de médaille, mais elles tiendront!

Peinture

J'avais au départ prévu de déboulonner la structure du sol pour la déplacer et pouvoir tirer les derniers cordons de soudure et peindre derrière... Finalement, je ne l'ai pas fait, tant pis pour les 3 soudures manquantes, l'ensemble est déjà 10 fois plus rigide que ce que j'espérais ; même en le secouant de toutes mes forces, ça ne vibre pas d'un millimètre. J'avais même prévu des tampons caoutchoucs en haut pour éviter tout choc, mais il n'y a vraiment pas de risque... Et mon côté obsessionnel devra vivre avec la face arrière de la structure non peinte (je prends sur moi par contre!La raison de ce choix de ne pas déboulonner le tout, c'est que les soudures tirent sur la structure, la déformant légèrement : si j'enlève les vis au sol, ça serait une galère sans nom pour tout réaligner et reboulonner... Cet établi est un outil que je veux utiliser au plus tôt, pas un chef d'œuvre, alors pour une fois je prends un raccourci - ça reste entre nous hein.

J'ai volontairement laissé le haut des pieds du fond non peints parce que je viendrai souder dessus les supports pour l'étagère une fois le plan de travail en place, pour les ajuster au mieux.

Plan de travail

Commande de deux plans de travail chez Leroy Merlin, en 315cm de long et 38mm d'épaisseur plutôt que le 58mm initialement prévu, simplement parce que ça multipliait le prix par trois. Je prépare sa fixation en perçant 22 trous ø5mm dans la structure pour le visser par en dessous.Après une petite découpe côté droit pour ajuster le plan de travail au mur qui n'est pas à angle droit, et y'a plus qu'à fixer le tout avec des vis 70mm... Je rajoute ensuite l'étagère au dessus ; je trouve ça super pratique de pouvoir poser des trucs en hauteur juste au dessus du plan de travail quand on bricole, et ça me donne un plan vertical où installer 2 blocs de doubles prises... J'avais récupéré ces deux longueurs de cornière ajourée je sais plus où, mais bonne pioche, c'était pile ce qu'il me fallait ici! J'ajoute ensuite le morceau de plan de travail sur la servante : ça me donne un grand établi en "L", tout en gardant la mobilité de la servante. J'avais calculé la hauteur de l'établi principal pour que justement la servante avec son plateau arrive à la même hauteur...

Pour garder le plateau en place, je lui fais simplement des saignées à la défonceuse en dessous, dans lesquelles viennent se loger les rebords du dessus de la servante. Ça reste nickel à sa place, sans modification de la servante. Ce plateau est lui aussi découpé pour s'adapter à l'angle des murs, et pour se glisser autour de l'IPN au fond...

Et comme il me reste un bout de plan de travail, je l'ai mis sur le côté sur des tréteaux pour avoir un établi supplémentaire temporaire (spoiler alert sur projet en cours)...

Résultat final

Et... Tadaaaaaaaa!Le résultat est vraiment proche de mon concept Sketchup initial, et rempli sa fonction à merveille. Et voilà! Je dois encore fixer l'étau et câbler les prises, mais l'établi est déjà utilisé activement!

Posté le 06/01/2022 à 11:15

Happy New Year 2022

Bonne année à tous!

Bonne année à tous!Enfin, ayons des attentes raisonables : qu'elle soit juste légèrement meilleure que la précédente serait déjà un net progrès.

Spoiler alert, la vraie vie étant en avance sur les articles publiés ici (ce qui est une façon de dire que je suis à la bourre sur mes articles) : la cox '59 roule! La photo ci-dessus a été prise il y a quelques jours, en balade autour du cap d'Antibes.

Un article est en fin de realisation sur le remontage du moteur et son premier démarrage, mais ça prend du temps à écrire, traduire, etc... Un peu de patience!

Un autre article à venir très rapidement est la (re-)remise en route du 181, qui a été un "rabbit hole"... Attendez-vous à un article à rallonge du coup.

Pour conclure, le Père Noël m'ayant apporté une caméra 360°, j'expérimente... Je vous laisse avec deux vidéos réalisées ces dernières semaines. Bonne route!

Posté le 22/09/2021 à 21:30

Elvira : Réfection du Pied Moulé, épisode 10 : Boites de chauffage

épisode 10 : boites de chauffage

Boîtes de chauffage

Je n'avais à la base que jes J-Tubes sur mon moteur ; je pars donc d'une base de boîtes de chauffage pied-moulé d'occasion. De la rouille (un peu), quelques coups, quelques trous, un mécanisme bloqué et un levier manquant... Rien qui ne se règle avec un peu de patience, un MIG et du WD40.L'un des mécanismes (levier articulé) est bloqué par la rouille ; le WD40 n'y fait rien, et à force d'insister, le tube-palier saute... Ce qui me permet de le mettre à l'étau, et après un peu de persuasion, il finit par se débloquer. Je le remet à sa place avec un point de soudure bouchonné, et zou.

De l'autre côté, le mécanisme n'est pas bloqué, mais il manque le petit levier pour actionner le mécanisme... Avec un bout de scotch de peintre, je copie la forme de celui présent sur l'autre boîte. Deux coups de scie, quatre coups de lime et deux trous plus tard, j'ai une copie prête à souder en place (bouchonnage encore). Les pièces sont finalement peintes à la peinture haute température Rustoleum en bombe (supposée tenir à 650°, mais je ne me fais pas d'illusions). La visserie est microbillée, et y'a plus qu'à remonter le tout.

Toles sous moteur

Pour que le système fonctionne, et que l'air soit forcé dans l'habitacle, il faut que les tôles sous les cylindres soient présentes, avec leur volet qui se ferme pour rediriger l'air. Je n'avais pas ces tôles sur mon moteur, et elles ne sont pas évidentes à trouver aujourd'hui (jamais faites en repro non plus). Mais avec beaucoup de patience sur les sites de petites annonces, et quelques billets, on finit par trouver.Bref, après avoir galéré, j'ai fini par en dégoter une paire propre, avec juste une languette de volet cassée... Nettoyage à l'essence F et nettoyant freins, puis microbillage pour virer la peinture d'origine qui s'écaille. Et comme ces tôles sont sous le moteur, exposées aux gravillons de la route, je leur passe simplement deux couches d'Hammerite au pinceau, ce qui les protégera mieux que la peinture carrosserie. Voila un la tole gauche telle que je l'ai trouvée, et la droite après traitement: Je m'occupe ensuite de réparer la languette du volet sur l'autre tole : un coup de MIG plus tard, c'est réglé. Sablage en règle et on repeint tout ce petit monde : Et.... Taaadaaaaa!!

J'ai au passage changé le cable de commande des volets (bien graissé), avec les petits caoutchouc en sortie de chassis qui vont bien, et monté des attaches neuves sur les leviers de commandes des boites de chauffage ; y'a plus qu'à remonter tout ça dans la caisse, et s'assurer que le système de volets fonctionne correctement!

Mais ça sera pour le prochain épisode!

Posté le 09/09/2021 à 12:53

Elvira : Réfection des Freins / Pédalier

Elvira '59 :

Réfection des Freins & du Pédalier

Réfection des Freins & du Pédalier

Alors oui, je n'ai pas énormément roulé, mais je ne suis pas à l'aise de continuer à conduire sans savoir exactement ce que j'ai sous la pédale du milieu - surtout que mon fils a bientôt 4 ans et n'attend qu'une chose, c'est de pouvoir partir balader dedans ! De plus, la (trop) longue immobilisation de la voiture ne lui a pas fait du bien, et j'ai déjà eu les freins qui bloquaient alors que j'essayais de déplacer la caisse à la main.

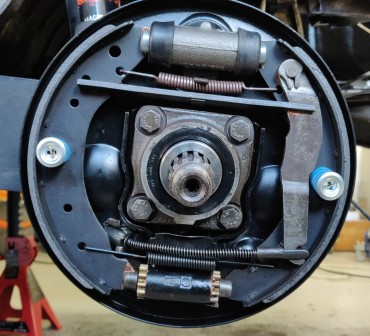

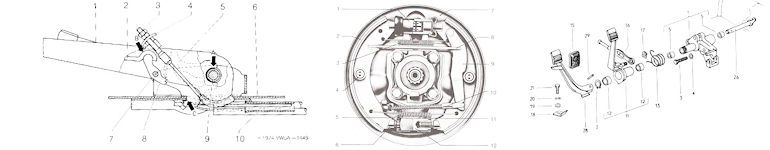

Alors on y va, le grand chelem, on refait tout à neuf : maître-cylindre, cylindres de roues, tambours, flexibles, garnitures, ressorts... Et tant qu'on est les mains dedans, roulements et kit étanchéité en même temps. Les cylindres de roues, tout comme le maître-cylindre, avant d'être posés, sont démontés, nettoyés au liquide de freins (brosse à dents power), et graissés avec une touche de graisse ATE spéciale freins (miscible dans le liquide de frein DOT - attention de ne pas utiliser de graisse standard ici!).

C'est important parce que ces pièces, lorsqu'elles sont stockées trop longtemps, peuvent "coller", et du coup ne pas fonctionner correctement. C'est une manip de plus, mais la différence de frottement est flagrante.

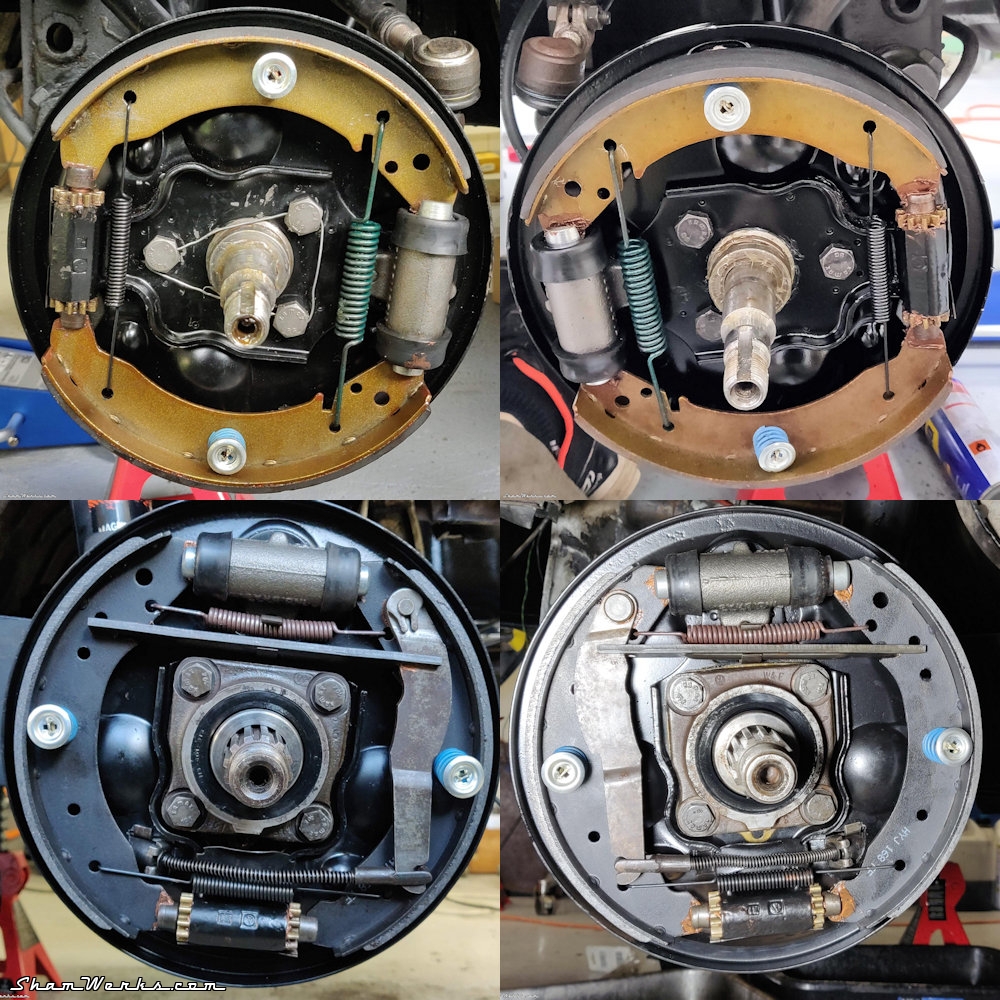

Freins Arrières

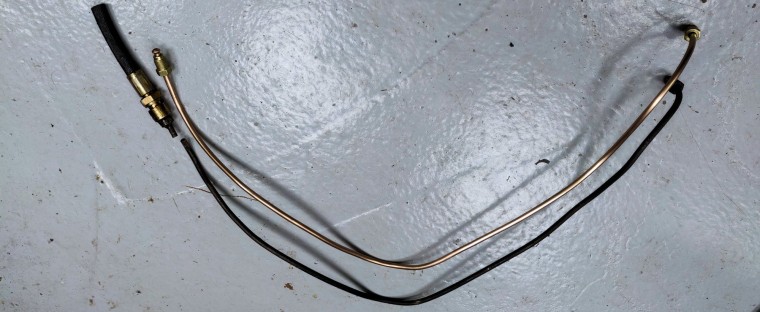

Allez, on s'attaque au démontage, c'est bien gras tout ça... Il était un peu temps de changer les garnitures, hein ?Mauvaise surprise au démontage, le flexible arrière droit était tellement serré et corrodé sur ses canalisations rigides, impossible de le démonter (et j'ai vraiment tout essayé, chaleur, dégrippant, pince étau sur la clé à tuyauter...). J'ai fini par tout couper et refabriquer deux canalisations rigides neuves. Comme tout est démonté, j'en profite pour changer les roulements arrière, en bricolant un outil pour les sortir. Ensuite comme d'habitude, nettoyage, microbillage, et peinture pour remonter du propre ; les plateaux sont nickel sous la crasse - surprenant. J'utilise de l'Hammerite en bombe pour la peinture, pour voir, je n'ai jamais utilisé ce produit sous cette forme avant. Il ne reste plus qu'à biseauter légèrement les garnitures de freins à la lime, je les dégraisse bien au nettoyant freins, et je remonte tout ce petit monde au propre, avec la petite touche de graisse cuivre aux points de frottement... Le tambour était à la cote limite (231mm) et bien marqué par les garnitures. C'était les tambours d'origine, datés juillet '59, ils avaient fait leur temps : hop, on change !

Les tambours arrière en repro n'ayant pas le trou prévu pour remettre les "oil slingers" d'origine, en avant, on mesure 12 fois, et on perce Ø8mm. Un peu de meulage à la Dremel coté intérieur, et ça se monte. Et il n'y a plus qu'à les mettre en peinture : dégraissage, ponçage léger, re-dégraissage, masquage, re-re-dégraissage, et trois couches d'Hammerite en bombe (hey, les gars de chez Hammerite, va falloir penser à me sponsoriser à un moment hein). Le résultat est propre, mais je ne suis pas sûr de la tenue dans le temps. A surveiller.

Un truc pour peindre en hiver : je mets les pièces dans un gros carton avec un chauffage de chantier devant... Ca permet d'avoir la température nécessaire pour que la peinture prenne correctement. Je mets d'ailleurs les pièces dedans avant même la première couche, pour qu'elles ne soient pas trop froides et éviter un phénomène de condensation ; la bombe de peinture aussi y fait un stage avant utilisation, pour que la peinture soit plus fluide à l'intérieur. Au passage j'ai remplacé les butées de suspensions qui avaient été coupées par l'ancien propriétaire pour éviter de buter après avoir droppé la caisse. Mais je roule à hauteur d'origine maintenant, autant les remonter propre... Et hop, deux tambours arrières prêts à remonter ; on sort la grosse clé dynamo pour serrer les écrous à 30mkg, et y'a plus qu'à passer à l'avant!

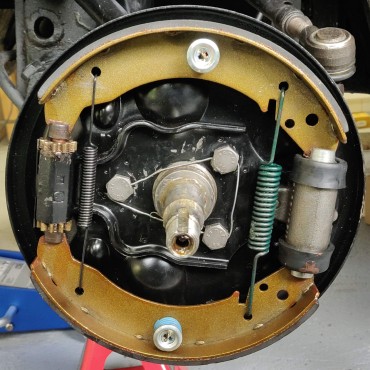

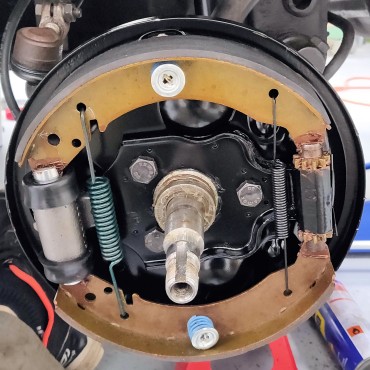

Freins Avants

Coté platines de freins, même punition qu'à l'arrière, mis à part un décapage à la brosse rotative sur perceuse parce que je n'avais pas encore ramené compresseur et sableuse de l'ancien atelier... Et puis pareil, on remonte tout à neuf, avec la petite touche de graisse cuivre... Attention, le plus gros des deux ressorts se montent coté cylindre de roue, je m'étais loupé la première fois...Coté intérieur, même punition qu'à l'arrière, j'ai refait le rigide de frein droit, qui était vraiment pas beau à voir. Les tambours avants étaient encore à la cote (tout juste), j'aurais pu les conserver... Mais après réflexion j'ai préféré les changer aussi pour passer tout en neuf et avoir l'esprit serein. Je garderai les anciens de coté à tout hasard...

Les roulements avant étaient bien cuits : cage cassée, billes qui foutent le camp, de la limaille dans la graisse... Il était temps. Ceux que je monte sont coniques à rouleaux, ce qui ne semble beaucoup plus mécanique que les roulements à billes qui était en place.

Je dépose et remonte les roulements avec la presse hydraulique que j'ai trouvée jetée aux encombrants - comme quoi ça vaut toujours le coup de faire les poubelles.

Pédalier

Tant que j'y suis, je sors le pédalier pour lui refaire une jeunesse. En plus, avant que je ne devienne propriétaire de cette voiture, certaines pièces avaient été repeintes d'un horrible jaune/vanille pisseux que je ne supporte plus depuis longtemps. J'en profite pour repeindre le pédalier, donc, qui passe en L87 PearlWeiss, comme les jantes... Décapant peinture, microbillage, apprêt, 3 couches de peinture : beaucoup mieux.J'utilise, pour voir, une bombe de peinture L87 de chez Sprido, à 18.50€. Le résultat est propre, j'essayerai probablement la même chose sur le volant à l'occasion. Pour me débarrasser entièrement de ce jaune vanille moisi, il me restera encore les embases de sièges, la colonne de direction, le volant, la barre sous la banquette arrière, et le cache de circuit électrique dans le coffre avant, mais ça devra attendre un prochain épisode.

Le frein à main, levier de vitesse et les jantes avaient déjà été débarrassés de ce jaune minable quand j'avais passé la caisse en carrosserie pour un voile... En 1998!

Bon, évidemment, rien n'est jamais simple, le câble d'embrayage n'était pas le bon modèle, trop court, et le câble d'accélérateur accrochait quelque part... Mais bon, après tout redémonté et monté le bon modèle, ça va mieux. Il ne reste alors plus qu'à filer un coup de pompe à graisse dans le pédalier, et le feeling aux pédales est complètement différent, bien plus fluide. On verra en roulant !

Allez, une purge et on a de quoi s'arrêter en sécurité, ça suffit pour aujourd'hui... Bonne route à tous!