Posted on 26/08/2024 at 11:41

30 Years!

Micro birthday post today... On that day of August 1994, I became Elvira's owner!

See you in 2034 for the 40th birthday?

Posted on 31/07/2024 at 15:35

Workshop organization : hardware trolley

In nearly 40 years of various DIY projects, I have accumulated a bunch of various storage boxes, for my screws, bolts, washers, dowels, terminals, etc. Obviously boxes of all sizes, making them difficult to organize and store, not mentioning find your way around easily.

It was time to find new...

AUER offers them in different sizes, with assortments of different compartments inside, and in standardized dimensions, stackable on my Euro standard storage bins of the same brand.

You can even customize them if you have a 3D printer, you can find specific compartments to print on Thingiverse and Printables.

This is free advertising, I'm not sponsored by them... But if by any chance AUER Packaging you're reading this...

I end up with ten of these organizers... And to be able to store them all, and find what I need easily, I made myself a custom-made trolley.

The structure will be in plywood, the organizers and trays being supported by aluminum angles screwed into the sides.

It was a bit boring to do: 36 aluminum angles, to cut then file to size, 54 corners to round, 108 holes to drill then mill and deburr... I was quite relieved when it was finished. For the plywood I use 18mm plywood for formwork (film-coated poplar from PointP ).

For the plywood I use 18mm plywood for formwork (film-coated poplar from PointP ).

The reason for this choice is that it is the cheapest plywood I could find, at €70 for a 250x125cm board (price at the time of purchase, it has increased since then)... You had to pay three times that in a DIY store.

The downside is that the boards are not perfect, as they are stored outside, so the edges can be a little delaminated and there is bot of little loss. But it is fine for the workshop and the price is unbeatable.

Cut with a plunge circular saw on a rail, and I screw everything together: I finished with 4 casters that had been lying around in a box for 15 years, and my new hardware trolley is ready!

Yeah, I know, it doesn't take much to make me happy right?

It was time to find new...

Organizers

I finally decided to invest a bit, and I replaced all my boxes (some of them I had since my teenage years!) with cases/organizers from AUER Packaging 40x30cm, featuring removable interior compartments. It's a beautiful product, very good quality, and even if it's not cheap, it's still much cheaper than an equivalent Sortimmo for example.AUER offers them in different sizes, with assortments of different compartments inside, and in standardized dimensions, stackable on my Euro standard storage bins of the same brand.

You can even customize them if you have a 3D printer, you can find specific compartments to print on Thingiverse and Printables.

This is free advertising, I'm not sponsored by them... But if by any chance AUER Packaging you're reading this...

I end up with ten of these organizers... And to be able to store them all, and find what I need easily, I made myself a custom-made trolley.

Design

I start with a design in Sketchup (no surprise if you've already been here): on the front my new organizers, and on the back as many flat trays of the same dimensions. And if necessary later, I can replace all or part of the flat tray with more organizers.The structure will be in plywood, the organizers and trays being supported by aluminum angles screwed into the sides.

Fabrication

The aluminum angles come from a stock of offcuts bought for cheap on LeBonCoin (the french Craig's List) : €40 for 14kg of ali angles, I have plenty left in stock! The same thing in a DIY store would have cost me an arm, a leg, and my son's soul: there are more than 12 linear meters in all!It was a bit boring to do: 36 aluminum angles, to cut then file to size, 54 corners to round, 108 holes to drill then mill and deburr... I was quite relieved when it was finished.

The reason for this choice is that it is the cheapest plywood I could find, at €70 for a 250x125cm board (price at the time of purchase, it has increased since then)... You had to pay three times that in a DIY store.

The downside is that the boards are not perfect, as they are stored outside, so the edges can be a little delaminated and there is bot of little loss. But it is fine for the workshop and the price is unbeatable.

Cut with a plunge circular saw on a rail, and I screw everything together: I finished with 4 casters that had been lying around in a box for 15 years, and my new hardware trolley is ready!

Resultat

This trolley slides along the workbench, at the same height, and by moving it I can easily access the milling machine behind. I use it all the time, and it's fantastic to finally find the bolts/washers/dowels you need right away - I only regret not having done it sooner!Yeah, I know, it doesn't take much to make me happy right?

Posted on 30/06/2024 at 07:44

Kitty Injection : 1776 part. 3 : Short Block

1776 / Part. 3

The Short Block

Actually, the last episode of this series dates from June 2014 ... Yeah, I'm not exactly an example of speed, right?

As a consequence, those of you with a keen eye will note that some photos were taken in my old workshop , and others in the new one...

Come on, let's not lose hope and continue with the closure of the "Short Block".. It's high time we put all these parts together to make an engine: I won't lie, I'm getting a little impatient for this engine to run...

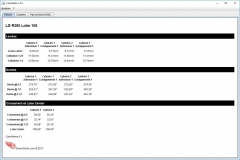

Metrology & methodology

I get everything I can through metrology on this build, so as to avoid any unpleasant surprises - and to satisfy my OCD.So I'm taking out all my metrology tools collected over the years: micrometers and their calibers, bore comparator, adjustable gauges (not in the photo), calipers, thickness gauges, etc... Well, I know that I'm not doing this in a clean room under controlled temperature, nor with regularly calibrated tools, but within a few hundredths I should be pretty good. Obviously this requires a bit of organization; to be able to find my measurements easily, and compare them to the VW tolerances, I note everything down in an Excel table (well, actually a Google Sheet). This allows me to access it from anywhere, note the values in the workshop when I measure them, and check the tolerances at a glance.

You can see the result below, or by following this link to have it in full screen: metrology 1776 KG.

At the time of writing these lines the compression ratio is not correct since I haven't taken care of the cylinder heads yet, but I will update the sheet when I do.

Crankshaft

This is a part that I had to chase for almost 7 months because of a not very well-organized parts dealer... In short, fortunately I have a father-in-law in the US to ensure stewardship on this one! Thank you Yves!So, it's a Scat Volksracer 69mm counterweight crankshaft, "Straight shot" oil galleries and not "cross-drilled", forged in nitrided 4340 chromoly... Beautiful beast. Although the crankshaft is sold as supposedly already balanced, I still got it balanced myself (at Feller's), with its flywheel and clutch mechanism; the damper pulley had already been balanced on its own. At least I would have a complete line that runs smoothly! (thank you Loïc for lending your crank shipping crate)

The alterations made to the crank by the balancer are not negligible, for a supposedly balanced part... Food for thoughts. It may be a beautiful piece of engineering, but it still goes through metrology, after a thorough cleaning (acetone to remove storage wax, brake cleaner, and cleaning brush for rifles in the galleries). Result in the spreadsheet above, everything is on point. Next!

Bearings

Each bearing (VW NOS original) is identified with a marked, and its oil groove aligned with its oil supply gallery; in some cases the gallery was half blocked! A touch of paint around the edge of the oil inlet, transfer to the bearing, machining with a pneumatic milling machine, finishing with sandpaper... And that's it. Okay, now it's a matter of measuring the clearance between the crankshaft and the bearing... In the end, that's what matters, and there are several ways to go about it.VW recommends a clearance of 0.04mm to 0.10mm on bearings 1 and 3 (wear limit of 0.18mm), and of 0.03mm to 0.09mm on bearing 2 (wear limit of 0.17mm) - a little tighter therefore, normal, it is the central bearing, the one which absorbs the most efforts.

They also recommend 0.05mm to 0.10mm (wear limit of 0.19mm) on bearing 4 (the one which is smaller, on the pulley side), but I am not equipped to measure it; not a problem, it is less vital than the other 3.

Okay, let's move on, we're going to measure these clearances...

First method : find the difference between the inside diameter of the bearing and the diameter of the crankshaft journal. See measurements in the spreadsheet above.

This method works fine I guess, but requires to be very accurate, as measurement errors add up. And when we're talking about hundredths of a millimeter, the temperature of the tool itself can influence - and you can imagine that my garage is not thermoregulated, eh...

Second method : we take the minimum diameter on the crank bearing; we block the micrometer on this value, whatever it is, we will not even read it. We will then calibrate the bore comparator to zero using the blocked micrometer: we can then directly measure the bore/bearing clearance with the comparator.

This is my favorite method, the most accurate in my opinion. Third method : Plastigage.

For those who don't know, it is a sort of soft plastic filament, which you clamp between the crank and the bearing. Then you tighten the case to torque, the filament gets crushed, and you then measure its width using a small scale supplied with the product, to figure out the clearance between the parts.

It’s a vintage method (the product has existed since 1948); not the most accurate in my eyes, and usable only on bearing #2 (bearing in two parts)... But it requires little material and it is easy to implement. I went through all three methods of measurements and got consistent results, within VW tolerances.

Validated!

Flywheel

On the flywheel side, I keep the one I had original, which I got machined to get it lighter and drilled for 8 dowel pins (reamer finish): The clutch mechanism is a Kennedy Stage 1; it got a mark after balancing (in yellow) to put it back in the right place at assembly time:Camshaft & Lifters

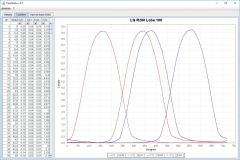

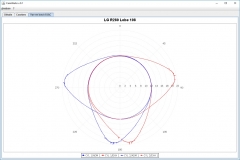

The camshaft is an L&G R280 Lobe 108°. To check its characteristics I built a camshaft measuring bench , I'll let you follow this link to check the details. I use double-shouldered bearings, to have 360° guidance of the camshaft, not just the original factory 180°; however, it is necessary to check the axial play of the camshaft.On the first assembly, I have zero play, the camshaft is in a sliding fit... No bueno.

Before removing any material from the bearing, I follow the Jake Raby method (see here / thank you Vince for the info): crankcase closed and torqued tight, I tap with a mallet and a brass cylinder on each side of the camshaft to seat the half-bearings #3 (pulley side). I then measure the axial play and...

Disappointment, the play is still at zero. I did follow the method, I hit firmly, but that was not enough...

So we take out the surface plate, 400 grit sandpaper with oil, and we are going to slightly sand down the bearing faces to get the required 0.1mm . To make the operation easier, I made a small tool to align the bearings halves: an old dead camshaft, grinded down to keep only the part on the pulley side.

This allows you to properly align the two half-bearings, and to sand them simultaneously, in a very uniform manner. A bit on one side, we turn the half-bearings, a bit on the other, making figures 8 on the sandpaper... Thanks Laurent for the advice, it works great!

Going slowly so as not to remove too much material, I remove little by little what is necessary... After the 3rd assembly/disassembly, I have just 0.1mm of axial play, that's all Good! I finish with 600 and 1000 grit sandpaper (with oil) for a smooth surface finish. Then, a small modification of bearing #1 (flywheel side): originally it partially obstructed the oil return gallery... A cut-off disc on Dremel and 10 seconds later, and the problem is solved (after removing any burrs with a file and fine sandpaper).

Finally, the holes on these #1 half-bearings are not chamfered: a light stroke with a countersink, held at fingertips, solves this. Not that it's mandatory as a modification, but hey, in for a penny... And remember that chamfering is what separates man from beast (I'll pay my round of beers to the one who has the reference). There you go, after a quick deglazing with a used Jex pad, the bearings are ready.

Connecting rods

These are original VW connecting rods (311B) that I had microblasted, checked and re-sleeved at Feller's.I then balance their weight, all within a tenth of a gram interval. To remove the bulk of the material I use a paddle disc on an angle grinder (it seems clumsy, but it allows you to work quickly and leave a good surface finish), and I refine with an electric file. Going through with metrology obviously to check everything... Validated.

Nuts and Bolts

All original bolts (screws, nuts, studs)were cleaned with WD40, then microblasted and reworked with taps/dies (M12x1.5 and M8x1.25).Everything then goes to cold bluing (Brunifast), mainly for aesthetics (and a little protection against corrosion): careful degreasing (brake degreaser, acetone), 3 minutes in the Brunifast bath (at 20°C min), rinsing with water, drying, and finally a bath in engine oil for at least an hour to set everything.

I had already explained the method in my article on restarting the 181 , I will not detail it further. For their part, the cylinder head studs are cleaned on the lathe, being careful not to leave a finger there, it's not necessarily a very safe approach!

First cleaning with a scouring sponge and WD40, then a quick sanding with 600 grit, a rotary brush on a drill to clean the bottom of the threads... And finally passing the threads through the die, to ensure a correct reading with the torque wrench when tightening the cylinder heads to torque! I know, it's a few hours of work here just for hardware... But it's cleaner and it's such a pleasure to assemble afterwards!

Closing the case

FINALLY!A quick review of the products/compounds used during assembly:

- Loctite 518: for crankcase assembly planes - the smell is super addictive.

- Loctite 577: thread sealant.

- Loctite 273: normal blue thread lock.

- RTV silicone: under the washers of the 6 M12 studs

- Wynn's Super Charge: used as assembly oil, it is very thick, it sticks well to the bearings, limits friction a little during the first assemblies, and will later mix with the engine oil.

- ZDDP grease: for the camshaft and lifters, to limit wear in the first minutes of engine life.

- WD40: with a piece of used Jex pad, to clean the crankcase joint surfaces, and deglaze the bearings.

- Acetone and Brake Cleaner: to clean parts before assembly.

Two steps back...

Of course, true to my principle of “ it’s never simple ”, in reality it didn’t happen that simply.As I don't have a lot of free time between work and family, I try to optimize... And obviously, when we go fast, we take shortcuts and... we miss things.

Here, for example, I was convinced that my stock-stroke crankshaft turned without any interference in the case, I had turned it by hand in the half case, and it didn't seem to hit anywhere. So I skipped the trial assembly with torque tightening, and I "permanently" closed the case...

But of course, once closed, there was a counterweight that was rubbing!

Long story short, that was a day and a half wasted reopening the crankcase, taking everything out, grinding/sanding the edges in the block, cleaning 518 compound around the crankcase, cleaning the dried thread locker on the bolts (each thread, one by one, with a curved tip ), removing the silicone under the washers, re-cleaning the crankcase halves carefully to remove any magnesium dust, etc... Just to get back to the same step.

I'll summarize it for you in 3 photos and we'll get back to it

Closing the case strikes back

Take two of the closure of the block... This time it's the right one, eh?So I install (again) the lifters, crankshaft, camshaft, and oil pump. The bearings and camshaft receive their dose of ZDDP grease, and the periphery of the crankcase a thin layer of Loctite 518 (red in the photos).

Let's not forget the plug behind the camshaft, and check that the marks on the camshaft gear align with those on the crankshaft's... Taking a big breath, after checking 15 more times that I haven't forgotten anything, and finally I close the case.... again.

Loctite thread lock on all threads, a touch of RTV silicone under the washers of the 6 large M12 nuts, which are torqued in the prescribed order (in stages, starting at 1mkg, and increased to 3.5mkg in steps of 0.5 mkg). The nuts all around the block are tightened in a star pattern, also in stages, up to 2.5mkg - (15mm nuts with cylinder head washers thanks to the Berg conversion).

And finally... Tada!!!

That's it for now, see you around soon (I promise) for the Long Block!

Posted on 09/02/2024 at 11:44

Head lights, Tail lights, and new Shoes

Elvira :

Head lights, Tail lights,

and new Shoes

Head lights, Tail lights,

and new Shoes

Headlights

My headlights were not in great shape: pitted reflectors, damaged rims, difficult adjustment because everything was shaking around... They were long due for some improvement. I started by taking out all the parts that I had put aside for almost 30 years: I had several bowls, supports, various strappings... There's plenty to organize a set of decent headlights in there No??Well actually, no. I don't have what it takes to make a complete & coherent pair...

I'll allow myself a rant here, you'll excuse me: Dear La Poste, I hope you'll read this: I believe that you are at best a bunch of incompetents, at worst a company with dubious legal methods, whose lack of "customer service" reminds of the interstellar vaccum. I have no doubt that I share this opinion with others (including people who work at La Poste and have confirmed the internal disaster to me). #Fthemallthewaytothemoonandback

Long story short, I had to sell my last kidney to buy 2 replacement lenses... And again, I was lucky that only the lenses were damaged, no impact on the chrome or the reflector. Anywayyyyyyy... This misadventure leaves a bitter taste in my mouth, but now my headlights are great. I fitted them with LED lamps, they shine brightly and now I can drive at night with confidently!

Rear lights

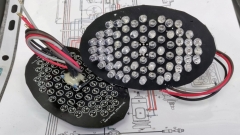

The original rear brake lights are not very visible, I wanted to improve safety... So I converted the lights to LEDs instead.I bought a pair of LED boards from Chip on TheSamba (see his ad here ). These boards include position lights, brake lights, and turn indicators. The original Elvira only had its semaphores, no flashing indicators, which is unsafe in today's traffic.

The flasher relay is replaced by one that is LED compatible, and in the process I add a motorcycle turn signal indicator ("beep")... Because otherwise I can ride indefinitely with the turn signals flashing!

I'll have to get back to it for the semaphores, which are currently completely disabled. But that will be the occasion for another article!

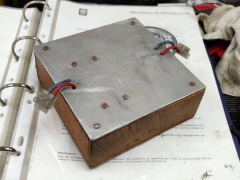

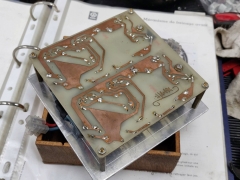

In short, to go back to the origin, I removed the autoradio, as well as the 6-12V converter that I had built at the time (dated 1994! With its homemade plywood case, we're talking real vintage there!). And I replaced the cardboard glove box with one from the same year, in very good condition. Lookin' better!

Tires and Baby Moons

Elvira was riding on Firestone F560 155R15, with portawall inserts. They were still good from a wear point of view, but... I had them installed 19 years ago! The rubber was dry and as soon as the road was slightly wet it became blurry while driving. It was time to sort this out.I wanted to go for real whitewalls, and after many comparisons of the few options available on the market (European Classics, Autobahn, Firestone, Coker...), I decided to go with Kontio (Finnish brand) "WhitePaw Classic" in 165/80R15, featuring a 64mm white sidewall, a radial structure, and an acceptable price (167€/piece, where some brands exceed 330€...). The European Classics are a bit cheaper, but the specialist I wanted to buy them from strongly advised against them!

Front wheels alignment was done right after tires where intalled : front axle happened to have 1.5° of toe out... Suffice to say that driving is much, much more reassuring now! Unfortunately the fitter who balanced my tires installed the weights on the outside... My fault, I should have clarified.

As it's visually terrible, so I replace them with equivalent weights glued on the inside, in the same places as those of the fitter...

Incidentally, the edge of the rim suffered from removing the clamped weights, I touch that up with a small paintbrush and glossy black lacquer...

As for the hubcaps, I had smooth baby moons for almost 30 years, but they were starting to show rust, and above all I wanted to return to a more "stock" look. So I bought the official VW reproductions with the stamped logo, pretty expensive sh*t but really nice product: thick sheet metal, stamped in logo and not (stamped out), deep chrome, protective paint on the interior...

I wanted the VW logos painted black like they were originally. I did so using the "spray & swipe" method:

- Acetone cleaning

- Light sanding inside the VW logo to help the paint stick (I go for 600 grit on my fingertip)

- Re-cleaning with acetone

- Glossy black spray paint (Motip), in a single fairly thick coat, using cardboard with a cut-out circle to limit overspray...

- 5-10 minutes later, when the paint has started pulling, I wipe off most of the paint with a cloth soaked in acetone, wrapped around the tip of my finger (you can probably skip that step, I'm not sure it's necessary).

- Finally, the magic trick: a cloth lightly soaked in acetone, wrapped tightly on a flat block of plywood (or a sanding block), and passed flat, in straight lines, over the logo to remove the surplus.

... ...and a nice little accessory.

A very practical little accessory, I added this USB charger hidden in the ashtray.

Installation requires drilling a hole in the ashtray support, and one in the drawer, well aligned so that the power cable can slide when opening/closing.

Good to know: a touch of vaseline on the cable allows it to slide more easily.

This charger allows me to have a Bluetooth speaker on long journeys without worrying about its battery running out... This charger is produced by a Brazilian company, fits well, but in France its retail price is pretty high for what it is (3D printed support with average finishes...). I broke the CB because I wanted to have it for an upcoming VW outing... But I'm sure there is a way to DIY an equivalent at a lower cost by getting the parts on AliExpress.