Posté le 21/09/2013 à 14:44

Albatross à Monaco

Du 11 au 15 Septembre derniers se tenait la "Monaco Classic Week", un événement bisannuel rassemblant dans la principauté des bateaux anciens : voiliers, vapeurs et runabouts/speedboats.

Du 11 au 15 Septembre derniers se tenait la "Monaco Classic Week", un événement bisannuel rassemblant dans la principauté des bateaux anciens : voiliers, vapeurs et runabouts/speedboats.

C'est l'occasion de voir une débauche de Rivas et autres Chris Crafts aux vernis impeccables, mais j'y étais surtout pour rencontrer John Fildes (AlbatrossMarine.co.uk) qui était descendu tout exprès d'Angleterre avec 2 Albatross!

Du coup j'ai pu aller faire un tour en mer en Albatross, 45 minutes poussé à presque 70km/h en pointe par le rare moteur Coventry Climax gavé par deux Weber double-corps : les Albatross étaient les plus petits bateaux de la Classic Week, mais aussi les plus rapides sur l'eau! Mes vertèbres s'en souviennent encore!

John était en plus accompagné du fils d'Archie Peace (créateur des Albatross)! Super rencontre, plein d'informations, de tuyaux, de conseils... Merci encore à vous deux!

Je vous ai ramené une vidéo de cette sortie en mer, qui ne retranscrit malheureusement pas très bien la vitesse de l'engin sur l'eau et le hurlement du moteur ; d'ailleurs, les chocs et l'eau de mer ont eu raison de mon Lumix!

Posté le 21/09/2013 à 02:32

Kitty Injection!

Upgrade

Injection Time

La majorité de la communauté VW voit ça comme un blasphème, mais il faut vivre avec son temps, l'injection apporte un agrément de conduite incomparable : moteur plus onctueux à tous les régimes, plus de trou à l'accélération, consommation et pollution en baisse, plus de carbus qui se désynchronisent/qu'il faut régler tous les 500km... Idem pour l'allumage qui va être contrôlé par le même boitier que l'injection, d'ailleurs....

Après avoir essayé la 1303 de Laurent (voir ici : 1303.skynetblogs.be - lien vers Archive.org puisque SkyNetBlogs a depuis disparu), j'étais convaincu. Et je suis parti à la chasse à la pièce!

Pour ceux que ce montage intéresse, je vais détailler dans les jours/semaines à venir les différentes modifications pour en arriver là, et les choix techniques que j'ai faits :

Electronique

Hardware

Electricité

Circuit carburant

Software

Moteur

Mais avant d'attaquer ce montage, je voulais donner un coup de propre au compartiment moteur, qui en avait bien besoin. J'ai commencé par commander un kit d'insonorisant moteur chez West Coast Metrics (via Slide Perf) : joli produit, mais l'aspect ne me plaisait pas.

J'ai donc fini par nettoyer toutes les marques de colle : au total 6 heures de boulot avec un bidon d'acétone de 5 litres (gants épais et masque à cartouche obligatoires!)... Mais au moins, c'est propre!

A suivre très vite, donc!

Posté le 18/09/2013 à 01:27

Kitty Upgrade : Passage en Trompettes Courtes

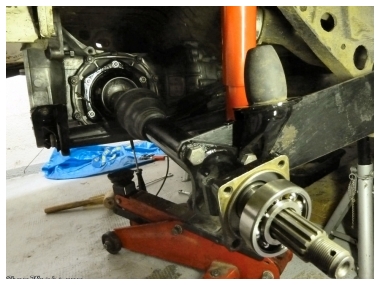

Mon KG étant un '68, son train AR est en trompettes longues, en passant en courtes je gagne 3cm de voie de chaque coté... Donc en avant, je déniche un set de trompettes courtes sur LeBonCoin, y'a plus qu'à!

La procédure est décrite dans les VW Tech N°14, et N°15, et le calage des arbres dans le N°60 ; pour avoir une référence, je photocopie tout ça et les met dans un classeur, dans des pochettes plastiques, comme ça pas de prob avec les doigts gras au garage...

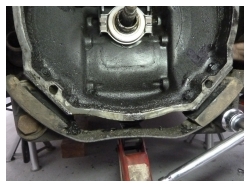

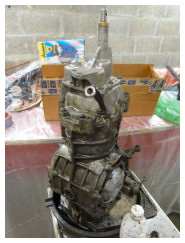

Le moteur est descendu sans trop de problèmes (merci Flo pour le coup de main), mis à part un écrou d'échappement trop rouillé... J'ai eu le dernier mot avec une scie à métaux, de toutes façons l'échappement sera changé. La boite suit rapidement derrière, et rejoint le plancher des vaches. Surprise au démontage, les deux silent-blocs coté moteur étaient proprement sectionnés, et la traverse gentiment tordue. Quelqu'un dans le passé de mon KG ne savait pas où placer son cric... À l'achat de la voiture le vendeur m'avait dit que la boite et le moteur avaient subi un échange standard chez VW en Afrique du Sud, et que la boite était une 8x31 (couple conique long).... Confirmation au démontage, code AS sur la boite, c'est bien une boite 8x31 "récente" (post 72), et ça, c'est une bonne nouvelle.

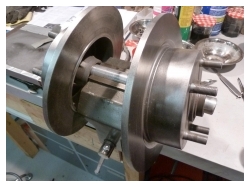

La boite est dépoilée de ses trompettes en utilisant un extracteur de chez Casto-Merlin que j'ai modifié. Les soufflets ont bien besoin d'un remplacement...

Les planétaires sont extraits, non sans difficulté car le calage n'avait pas été fait lors de son échange standard : trop de jeu latéral, le clip talonnait dans son logement, ce qui l'a maté. Il faudra jouer de la Dremel pour reprendre très légèrement la lèvre du logement, et permettre aux planétaires de sortir... La boite a alors droit au grand nettoyage de printemps : grattage du plus gros, puis essence F et dégraissant freins, un passage au Kärcher eau chaude (Éléphant Bleu powah), et un coup de brosse rotative en nylon montée sur perceuse pour la finition.

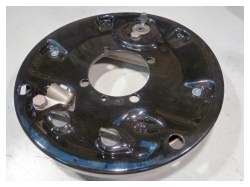

Le différentiel est soigneusement bouché au Duct Tape pour éviter de mettre des m*rdes dedans durant le nettoyage... Pour ceux qui n'ont jamais vu la différence, voilà les deux modèles trompettes côte à côte : courte à gauche (jusqu'en 66), longue à droite (après 67). Attention, il existe aussi un troisième modèle, dit "mi-long", spécifique aux modèles '67.

La version courte fait gagner environ 30mm ; les axes de transmission, eux, sont plus courts d'environ 45mm : en fait, les cannelures elles mêmes font 15mm de moins, c'est là qu'est la différence... Il faut d'ailleurs usiner les nouveaux tambours pour leur retirer 15mm pour ce montage!

Tant que les trompettes sont sur l'établi, je décide de leur monter des soufflets non fendus, comme à l'origine, histoire d'éviter les fuites d'huile que les soufflets fendus causent souvent.

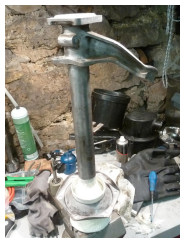

Pour monter des soufflets non fendus, deux solutions : soit on a une presse hydraulique pour sortir les manchons (l'extrémité de la trompette coté roué, en fonte), on disque le support de rigide de frein, et on glisse le soufflet le long de la trompette... Avant de remettre le manchon en place, toujours à la presse.

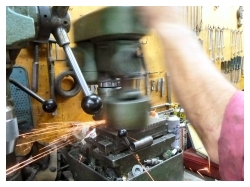

Ou alors, si on n'a pas de presse (comme moi), on utilise la solution décrite dans le manuel d'atelier VW d'époque ; ça a l'air un peu barbare, mais en fait ça se fait bien!

Pour ceux qui voudraient se lancer, j'ai fait une petite vidéo pour décrire comment faire (et ne pas faire, j'en ai déchiré un!) : Vous pourrez trouver d'autres vidéos de cette manip dans cette Playlist YouTube.

Voilà le résultat : clean non?

En détaillant le soufflet que j'ai fendu au montage, on voit bien qu'il a lâché au niveau de la "soudure" du moulage, il doit y avoir un point de faiblesse à cet endroit, et j'ai commis l'erreur de forcer sur ce point précis avec mon tournevis... Si vous tentez l'opération, ne faites pas comme moi!

Et quelques jours plus tard... TAAAADAAAAA!

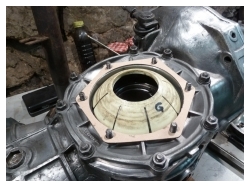

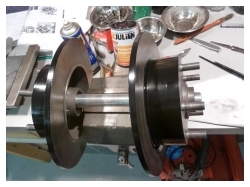

Comme dit plus haut, le calage des planétaires n'avait pas été fait. Du coup, je reprends ça comme il faut...

Il y a 3 jeux à contrôler sur les planétaires, la RTA donne les tolérances :

- entre les cotés de la queue de poisson et le corps du planétaires ; entre 0.03mm et 0.1mm avec une préférence pour un jeu serré. Ma cale la plus fine, 0.04mm, passe serrée à droite, et 0.05mm à gauche... Je considère que je suis bon ; je suis juste un peu serré parce que les repères couleur ne correspondent pas entre les arbres de transmission et les planétaires.

- entre le plat de la queue de poisson et les demi-lunes : il faut entre 0.1mm et 0.3mm, avec une préférence pour 0.15mm/0.20mm. Je suis dans les clous, 0.15mm à gauche, 0.16mm à droite.

- C'est maintenant que ça se complique : planétaires dans le différentiel, cale à oreille et circlip en place, on doit avoir entre 0.05mm et 0.2mm, avec une préférence pour un jeu serré. Or j'ai 0.27mm à droite et 0.25mm à gauche... Pas bon.

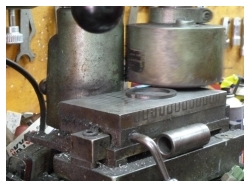

Plan B, donc, j'ai commandé les rondelles calibrées chez VW Classic (2 mois d'attente, faut être patient... Je prend des circlips neufs en même temps, pour avoir un montage propre), en 3.9mm, 4.0mm et 4.2mm (la cote max), en espérant avoir le bon modéle au montage. D'ailleurs au passage on voit deux qualités différentes : les 3.9mm et 4.2mm sont bien finies, et précisément calibrées ; en revanche celles en 4.0mm ont un état de surface vraiment moyen, et surtout accusent 4.42mm au pied à coulisse! Evidemment, ça serait trop facile, je n'ai pas la bonne taille, les 3.9mm sont trop fines, et les 4.2mm rentrent tout juste...

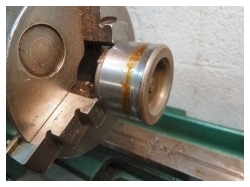

Direction chez JLC (merci Jean-Louis!) pour quelques coups de rectifieuse bien placés... Et hop, calage aux p'tits oignons, presque serré, je serai nickel après quelques kilomètres! Ensuite j'installe un nouveau joint spi sur la boite tant qu'elle est sur l'établi (le plus difficile est encore de retirer l'ancien joint, mais ça se fait bien avec ce type d'outil trouvé sur eBay), et je remonte mes trompettes en calant mes flasques : 3 joints papier d'un coté, deux de l'autre.

Il n'y a plus qu'à enquiller la boite à sa place dans la voiture... Enfin!

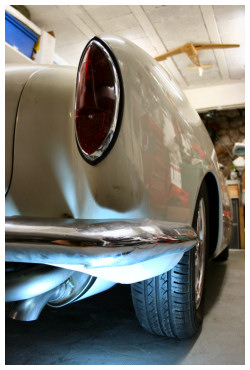

Je remonte le tout avec des silentblocs neufs et plus durs, roulements et joints neufs coté roue... Et finalement... TAADAAAA!!!

Tout ça pour ça! Au moins les roues passent largement, je dois même pouvoir augmenter un peu les cales derrière les jantes (là il y en a déjà, de 8mm seulement). Bon, par contre, il a l'air plutôt haut comme ça, va falloir songer à le rapprocher du sol...

J'ai pas résisté à l'envie de faire un coup de Photoshop rapide pour voir à quoi ça devrait ressembler!

Pas mal, mais ça sera pour plus tard!

Posté le 22/08/2013 à 12:07

Le Road Trip

Un petit clin d’œil à un blog que je suis de près depuis presque un an : LeRoadTrip.com !

Seb et Soizic sont en train de terminer leur tour du monde en Combi Split de 1966! Rien que ça!

Partis il y a 13 mois maintenant de Toulouse, ils sont passés (entre autres!) par les US, le Japon, l'Indonésie, l'Inde, la Thaïlande, l'Iran, la Turquie, la Grèce...

Ça fait un an qu'ils me font voyager avec leurs photos, et surprise, je suis tombé sur eux au meeting de Menton le week-end dernier! (cf. photo ci-dessus, cliquez pour agrandir, 2 photos à voir!)

Ça a été l'occasion de discuter avec Seb de leur aventure : Seb, merci pour ta gentillesse et tous tes conseils de voyage!

C'est malin, j'ai envie de partir maintenant...

Retrouvez tout leur voyage sur LeRoadTrip.com

Posté le 12/07/2013 à 17:20

Kitty Upgrade : Pédalier

Pour changer ce câble, il faut sortir le pédalier, mais quand j'ai vu sa tête, j'ai préféré lui redonner un coup de jeune avant le remontage! En avant, désassemblage / nettoyage / sablage / peinture, microbillage de la quincaillerie, remontage avec des pièces neuves...

Voilà le genre de contretemps qui me fout en l'air mon planning... Ça, et les délais VW Classic.

Le toucher des pédales est beaucoup plus souple qu'avant, j'ai hâte de pouvoir conduire avec!

Par contre au sablage une micro félure est apparue à la base de la pédale d'embrayage, il n'est pas impossible que je doive redémonter pour souder ça... On verra si ça tient une fois boite/moteur remontés.

C'est tout pour aujourd'hui, la suite très vite!

Posté le 11/07/2013 à 23:02

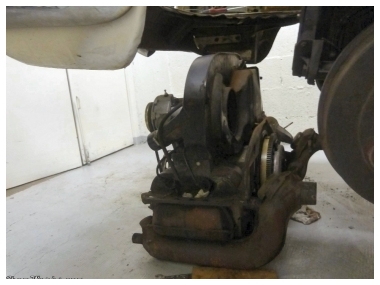

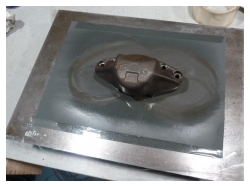

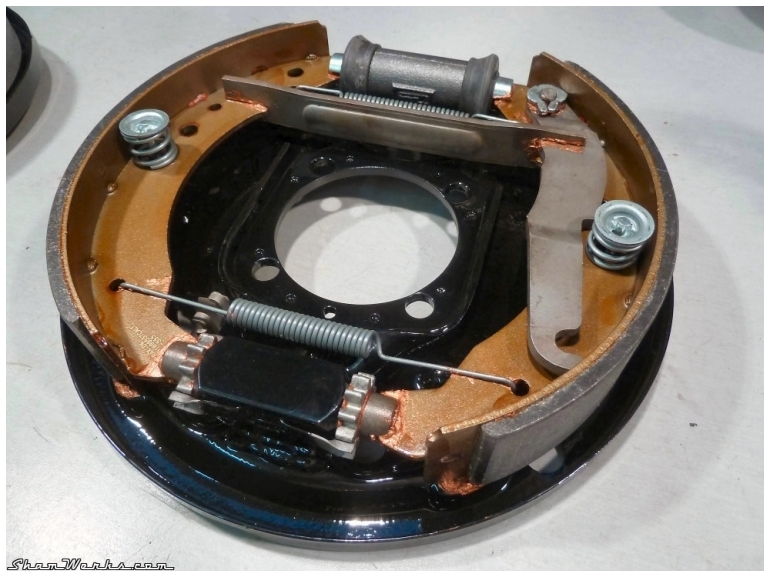

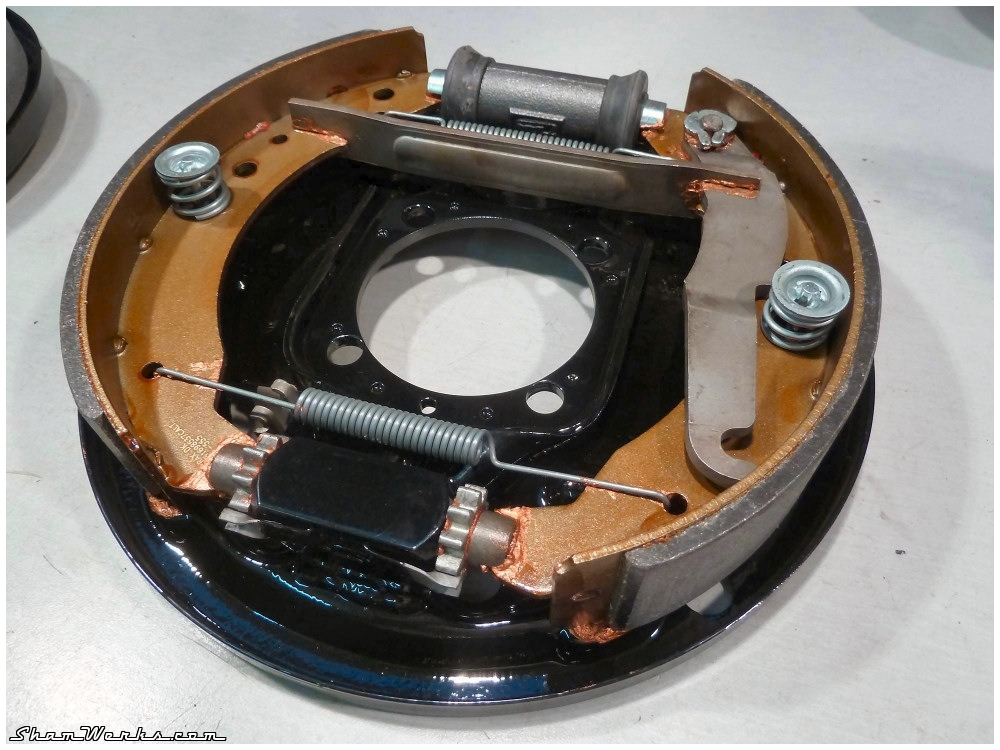

Kitty Upgrade : les freins!

Donc en avant, tant qu'on y est, on refait le tout à neuf!

À l'avant:

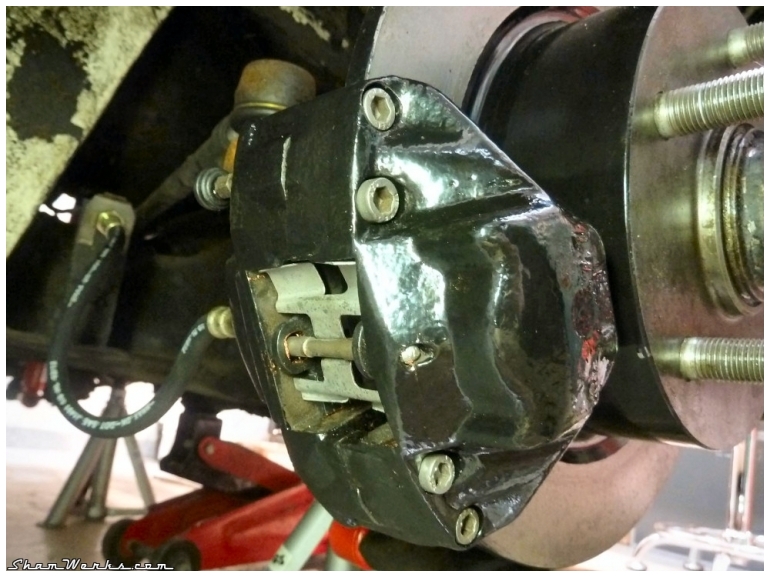

Changement des disques et roulements par du neuf (merci Laurent!), et réfection complète des étriers : kit réfection VW Classic, plaquettes et flexible neufs, boulonnerie microbillée, étriers peints (kit Foliatec). Je voulais les peindre en rouge au départ, mais finalement je trouvais ça trop "bling", noir brillant c'est quand même plus classe.Pourquoi les peindre? Pour ne pas avoir un vilain étrier rouillé qui apparaît au travers des branches des Fuchs!