Posted on 15/05/2016 at 23:20

Elvira : Rebuilding the 36hp, part 4 : Solex 28 PCI

episode 4 : Solex 28 PCI Carburetor

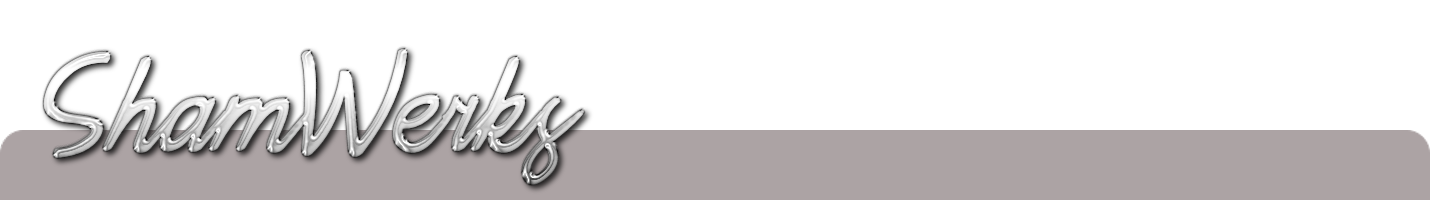

After 57 years, it was long overdue for a rebuild... Actually, I just found out about a cleaning method on a vintage motorbikes forum : they clean their carbies by putting their parts in boiling lemon juice, directly in a sauce pan! And I have to say, I was pretty amazed by the results!

So I tried the same approach, but using my ultrasound tank, filled up with 6 bottles of lemon juice, heated all the way up to 80°C!

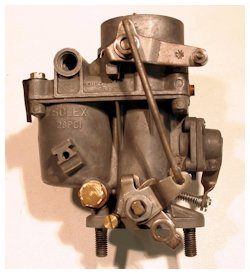

So after I disassembled the Solex, I let it soak in for 3 ultrasonic rounds of 20 minutes, after which I rince everything in clean water (ideally it'd have to be warm to avoid thermal shock) in order to remove any remaining acidity left by the lemon juice... Then a quick blow dry. I immediatly lube the rotating parts to avoid any oxidization... And the result is pretty neat!

I think the ultrasound are pretty useless here, being dampened by the particles in suspension in the lemon juice ; but they still help agitating the whole thing, and it probably helps.

I reassemble the carb with a renovation kit - all the gaskets were dry, the accelerator pump diaphragm completely rigid... It was time to do something about it.

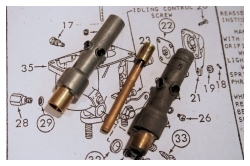

But obvisously, everything was going fine. Too fine. So as I was reinstallint the jet on the emulsion tube, lightly tightening it as I know it a fragile part... Crack. F*ck me.

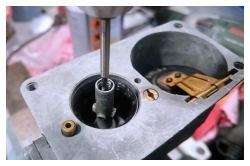

Fortunately, this emulsion tube can be bought NOS online on eBay in Italy... So 10 days later, here we go again, I replace the cracked tube... (note : there's an alternative to the NOS tube : one can buy a brass made replica at Bob Services : thanks SebCore for the info!)

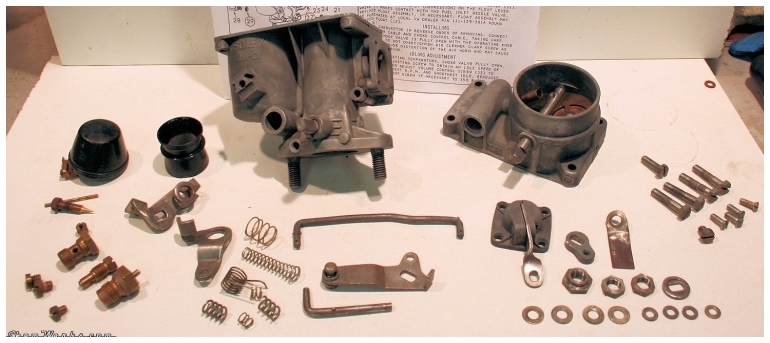

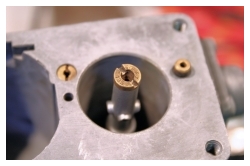

To extract the tube, I first tap it with an M3 tap, pull.... But only the brass part comes. Second try, I tap the remaining tube with an M5 tap, pull it... And this time it's out. Yes!

The new tube is inserted after heating the carb body with a heat gun (on "low", be gentle!). The tube itself is cooled down with a couple of squirts of brake cleaner fluid + compressed air blow. It's not settling in that easy, so it took some convincing with a small hammer and a drift punch, the carb being held in the vice. Again, gently! Now I only had to put everything back together with new gaskets, replacing as well the small metal pins on the linkage, with were prone to breaking due to their age.

And there you go, a new-ish carb!

It directly goes into a plastic bag, waiting for the holy day it will make my engine come back to life...

Posted on 28/07/2016 at 16:53

Elvira : Rebuilding the 36hp, episode 5 : Fuel Pump

episode 5 : Fuel Pump

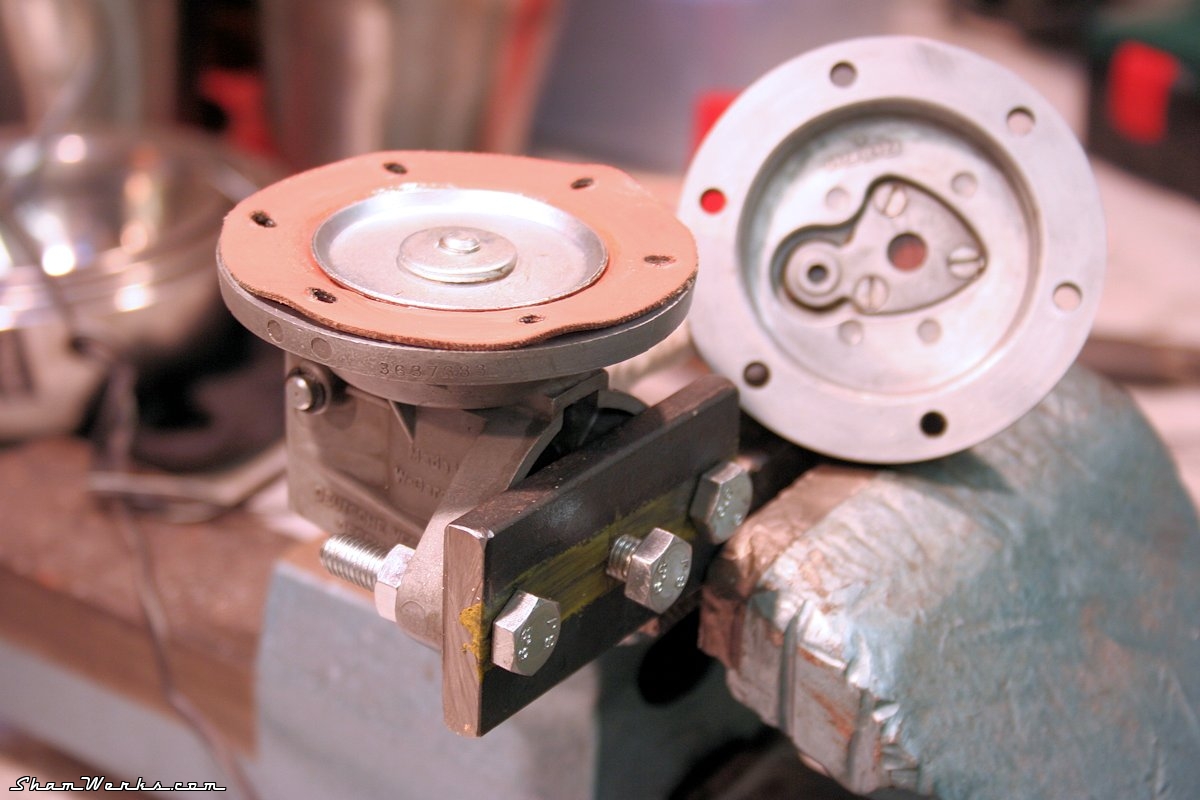

I've owned this car for 22 years now, and it has always run this very pump. It was long overdue for some TLC! After thorough disassembling, I first give it a good cleaning with a brush and some brakes cleaning fluid, to get rid of most of the gunk. By the way, I can see that event though the pump's membrane is completely rigid, it's still in working order and not leaking! Pretty amazing quality part, I doubt the new one will last that long!

Next, just as for the carburetor earlier, I dump all the parts into the ultrasonic cleaning bath, filled up with lemon juice. It looks like new when it comes out after just 20 minutes at 80°C. I rince everything thoroughly with clean water to neutralize the acid action. Before I put everything back together, I check that both pump halves are actually plane : 320 grit sand paper on my surface plate, a squirt of WD40, and I do 8 figures with each half. Right from the beginning, the sanding marks show it was far from being plane...

Ten minutes later, it looks much better! At least it should limit the risk of leaks right there... I reassemble everything with a BBT rebuild kit. The membrane (main part) looks good, but on the other hand, I will not use the two small levers provided in the kit (edit 20211017 : spoiler aler : I should have!), they look cheap and flimsy, I'll stick to the original ones that still looks pretty good. The main spring is much longer and strong than my original one ; I don't know if it respect the factory measurements, but if so, my spring was in dire need of retirement! In order to propermy install the membrane, you need to pre-load the pump ; this is supposed to be done using the VW328b tool (see it here on TheSamba), which I obviously do not own, so I make myself make-do one.

The 1958 workshop manual states that the pump's lever should be depressed by 35mm from the pump mounting plane ; so, a piece of laminated steel, three holes -one of which is tapped-, and there you go.

I finally just have to mount the membrane with a thin coat of grease, so that it slides smoothly in place, avoiding any "wrinkle" that may cause a leak... And BAM, an as-new fuel pump ! The inside is packed with grease, and it goes back on the engine.

NEXT!

Edit 2021/10/17

Well, finally, I should have used the lever parts from the kit... As the engine didn't start any more, I found out no fuel was coming to the carb, and I found the lever/arm thingy broken. The stronger spring may be responsible for the lever's untimely death.I put back everything together with the BBT lever, and it works perfectly (even though I still think these stamped parts don't really fill me with confidence). I also re-use my original axle, as the kit's one does look nice with its 2 circlips, but is too short for my pump's body. Anyway, back on the road!

Edit 2021/10/22

Do you remember when I was saying "The main spring is much longer and strong than my original one"?Well, I should have stuck with my initial gut felling and kept the original spring. The kit's one clearly puts way too much force on the lever... Which broke on me for the second time.

Except this time, I was on the road, for the first outing of Elvira in 14 years... And I rode back home on a tow truck.

Re-fixed, and back on the road.... Again. Hopefully I won't have to reopen this fuel pump anytime soon!

Posted on 25/10/2016 at 00:30

Elvira : Rebuilding the 36hp, episode 6 : Rocker arm geometry

episode 6 : Rocker arm geometry

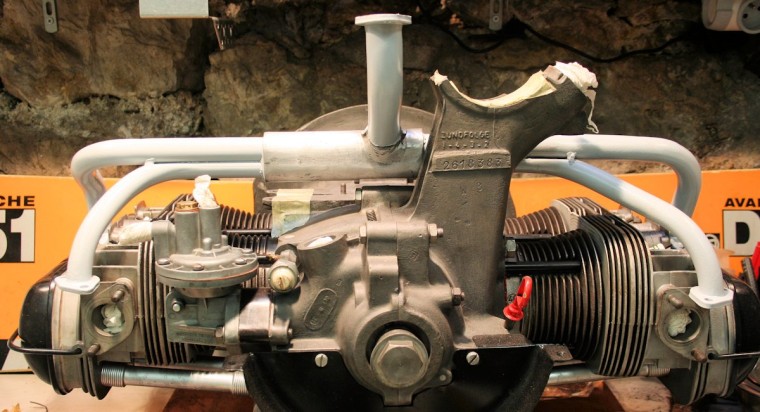

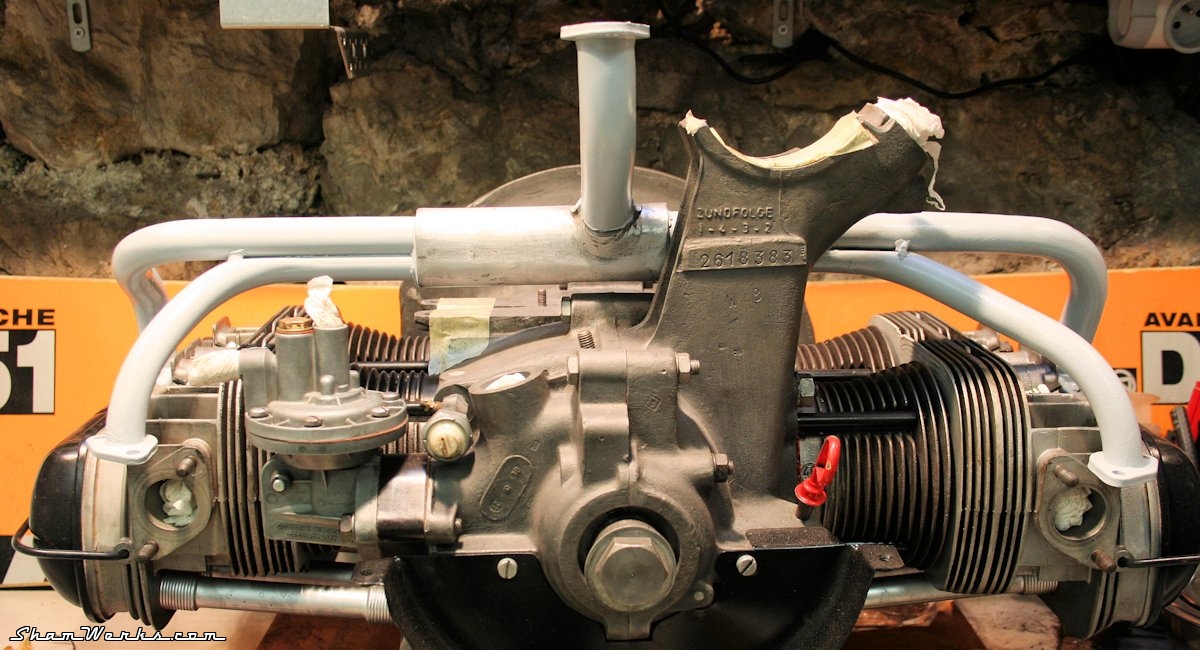

Since I've milled 3.2mm into each head, the whole engine is now 6.4mm less large...

So, I gotta shorten them pushrods! (and that's just the beginning...)

On 36HP engines, contrary to more recent T1, the lifter and the pushrod are one single part...

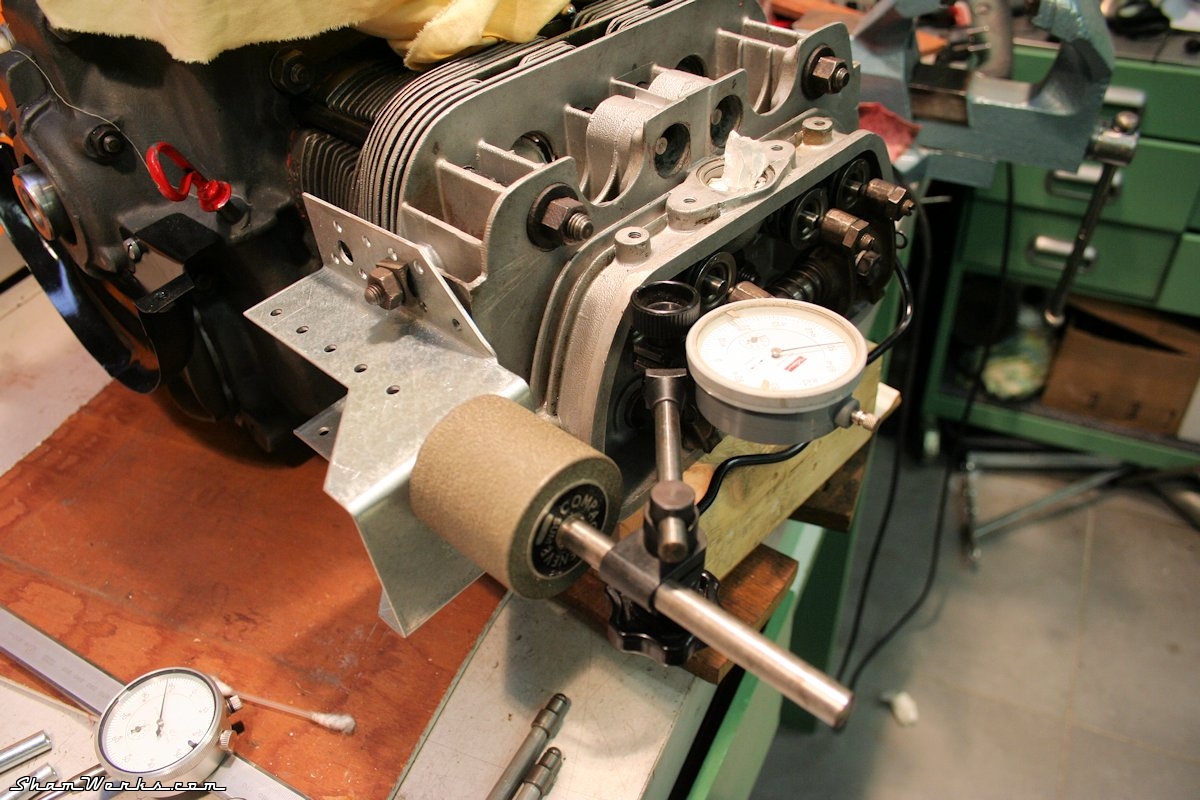

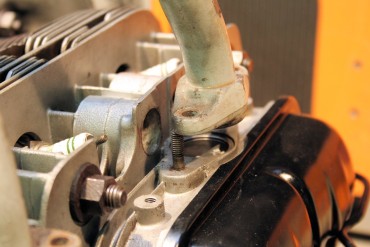

I start by making myself an adjustable pushrod to find out the right length : I grab an old pushrod, cut it in the middle, throw at it a length of threaded rod and a couple of nuts, and I'm ready to rumble. Next, I install a dial gauge to measure the total lift ; I measure 7.76mm at the valve, which is relevant with what I obtained with my camshaft measuring bench (check article here). I then turn the crank until I'm at half-lift (that is 3.88mm) : while in this position, the pressure screw on the rocker hs to be perfectly aligned with the valve stem.

Side note: some of you may argue that this shouldn't be measured at half-lift, but at the angle at which the valve has the maximum linear acceleration, as this is when you get the most mechanical constraints. From a mechanical stand point, that's right... But come on, this is just a 36HP, with chewing-gum valve spring, not a 2.4L with adamantium double valve springs running at 8000 RPM. The half-lift willl definitely but a good-enough approximation!

Anyway, I adjust the length of my pushrod, tryin to get the lifter in the correct position... Try, remove the lifters, adjust the rod, put back the lifters... After the 3rd try I had the correct length : 299.2mm, while the pushrods are initially 302.3mm long. That's 3.1mm I gotte take off of each pushrod ; it makes sense, since I got my heads lower by 3.2mm on one side, and 3.15mm on the other. To shorten the pushrods, I first remove the lifter part : it's pretty easy, you jut need to put the rod in a vise (in between two pieces of wood not to scratch it), and give a firm tap with a bronze piece on the lifter. The rods are then lathed down, using a W20 8mm collet. I also remove short of a 1/10th on the diameter over 12mm of length, unless you can't put back the rod into the lifter (trust me, I bent 5 of them trying). I suppose they had a machine at the VW factory that would hold the whole length of the rod to prevent bending.

To make sure the pushrod isn't bent afterwards, I just put it back into the engin case, and make it turn between my fingers : if it's still straight, it will remain centered into the tube! Obviously, don't push it all the way into the case, unless the flat side on the lifter will prevent you from making it turn. Pour vérifier que la tige n'est pas pliée une fois le poussoir : on la remet dans le bloc et on la fait tourner du bout des doigts : si elle reste bien centrée dans le tube enveloppe, c'est qu'elle est droite! Evidemment, il ne faut pas la rentrer à fond, sinon le méplat sur le poussoir empêche de la faire tourner.

Historical side-note

The pushrods on 36HP engines may contain a piece of wood inside (made out of beech wood) : actually that's known to be the only piece of wood in a beetle! (well, if you ignore the convertible tops obviously)My pushrods didn't have that piece of wood inside ; but I had another one (gift from Eric SIMON) which did contain that rod. But the actual role of this rod has never been really established...

(Edit 20161103 : Oops, forgot to add pictures right here!) I've read different theories on the subject :

- To make oil go up to the rockers thanks to capillarity effect : I don't buy it. No pressure, no flow, and the oil would actually drip back into the rod. Nope, not happening.

- Pumping effect due to the wooden rod going up and down into the pushrod... I don't believe it either, there's an actual oil pump pushing behind, I don't see how that would work.

- To dampen the vibrations and limit distribution noise by absorbing some of the harmonics : well, why not, could be.

- To limit the oil volume in the push rod. Thus limiting the weight of the pushrod, making the whole distribution lighter. Plus, upon starting the engine, you'd have less volume to fill up, meaning faster pressure build up. That could make sense ; the flow is anyway limited by the hole diameter on the lifter and on the rocker side : no actual need for the pushrod to be filled up with oil.

That's all folks, to be continued soon!

Posted on 06/11/2016 at 12:59

Elvira : Rebuilding the 36hp, episode 7 : intake manifold

episode 7 : intake manifold

Since I did not want to modify my original 36hp manifold, I found a spare one on LeBonCoin... There we go, I cut using a hacksaw, and I remove the dreadful 6.4mm! I take advantage of the accessibility opportunity to clean the inside of the heater tube, which was in dire need of some TLC. Definitely easier to do this while it's opened like that!

But I don't have access to the cut other side of the tube, next to the first tube I welded. I hoped that a nice clean weld on each side would do the trick, but when I wput it under pressure, it was leaking all over the place. So I got the Dremel out, and cut a window to get to the inside of this cut and weld it from there. I welded the window back in place, and this time it was air tight on the first try! Next step is as usual : sandblasting, 2 coats of rust-preventing primer, 3 coats of paint... And TADAAAAA!! Here's your 6.4mm shorter manifold! Yep, all of the above just for 6 f***ing millimeters! Dayum, you gotta love your compression ratio, right?!

Posted on 07/03/2017 at 21:18

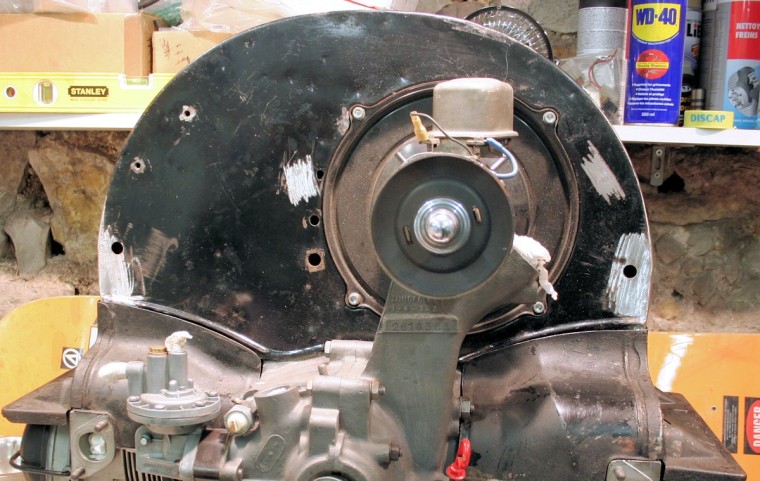

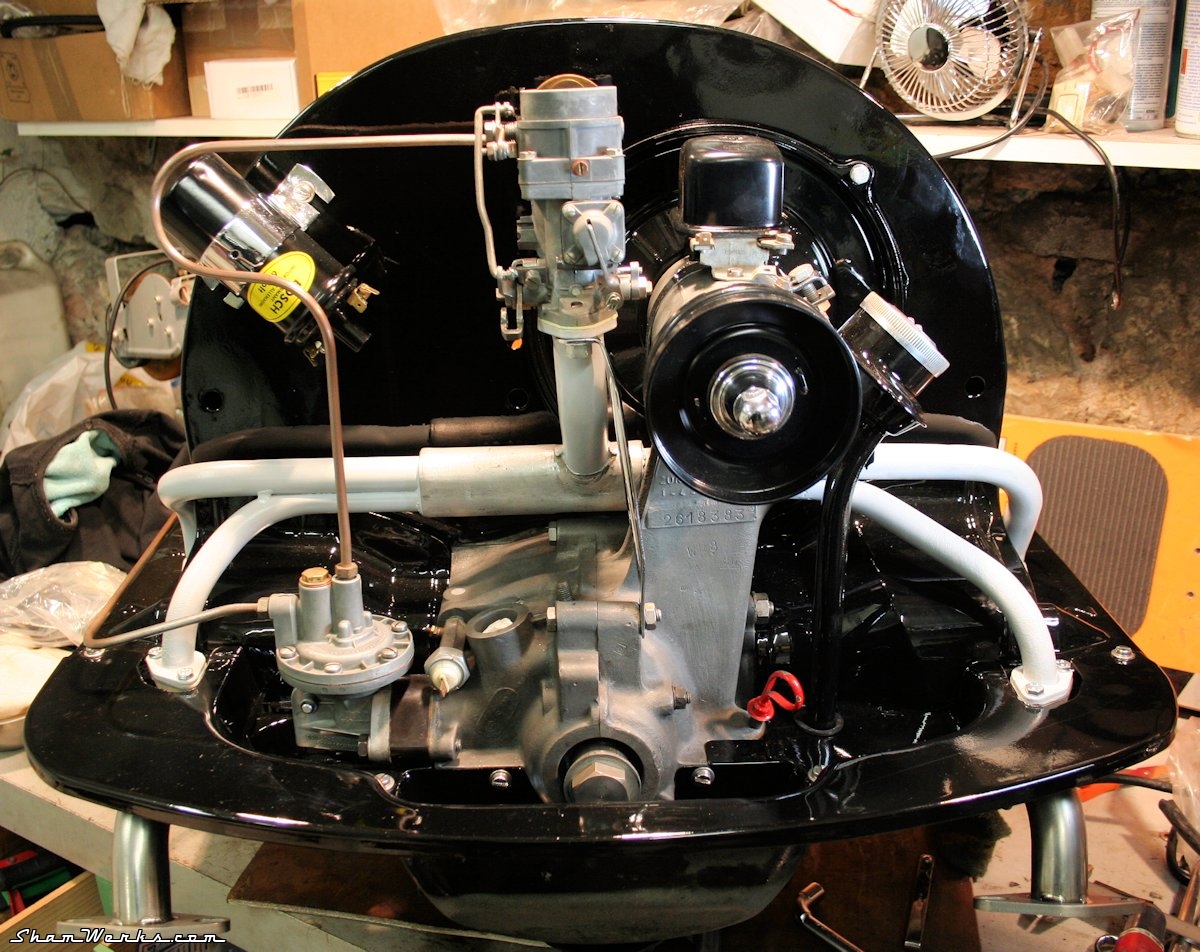

Elvira : Rebuilding the 36hp, episode 8 : cooler, tinware and shroud

episode 8 : cooler, tinware and shroud

Oil Cooler

I start by sprucing up my oil cooler. I put it under pressure to ensure it is still air tight, using a bicycle tire valve (same method I recently used for my intake manifold). It holds at 5.5 bars : we're good here.Thorough cleaning using brake cleaning fluid and compressed air, giving the whole damn thing a good shake to make sure I get rid of any muck sitting in all the nooks and crannies inside...

Then I give it a light sandblast to remove the flaking off original paint (I obviously first taped shut the oil in/out holes), and then a thin coat of high temperature spray paint, just to prevent rust. Just to make sure the sandblasting did not affect the oil cooler, I give it another pressure test ; still holds at 6bars, we're still good (#paranoid).

It then goes back on the engine with a couple of brand new gaskets. Next !

Fan shroud and tinware

Again, because of my modified cylinder heads, I gotta touch up the tinware to make it fit the new engine width.Since I'd rather keep my original tinware untouched, I managed to get my hands on a new set of tinware and fan shroud to modify them. That new shroud is slightly different than my original one, it doesn't feature the top recess (which makes room for the oil bath air cleaner)... Prolly an older shroud ; well, since I wanna move later to a two carbs setup... For the two over-cylinder tins , it's pretty straight forward : I just Dremel-cut 3.2mm at their base. Done. For the shroud, well, it's a bit more tricky. I make two triangular relief cuts on each side, which I then bend inward and weld back shut... And there you go, a 6.4mm narrower shroud.

Well, it did take a few hours to weld/grind!

I wanted to give a shot to this product for a while now, as a friend recommended it to me... Not exactly cheap (25€ the spray can at Vernicispray), but I gotta say, the result has NOTHING to do with that of a standard spray can! Shiny! Well, sure, as I used it in my dusty garage, it's not perfect by any means, but way good enough for engine tinware as far as I'm concerned.

In order to use these spray cans, you first have to hit the bottom cartridge, that holds the hardening component, then shake the damn thing a couple of minutes. You than have 6 to 7 hours to use the product before it hardens... So you need a bit of organization if you want to spray more to one coat!

Just one drawback I experienced : it might be because the temperature in my garage was too low, but by the end of the can, it spitted droplets instead of a nice even spray (even though I did heat the can before use by putting it above a radiator, and made sure the nozzle remained clean)... Just be careful.

The oil filler, small tin below fuel pump, and front/back half-moon tins all get their lick of paint as well... I did not originally planned to do so, but they looked dull next to the other shiny parts...

Generator

About a dozen years ago, I converted my circuit to 12V, using a rare 90mm generator (ref. VW 113903031E, ref. Bosch 0101206116), and a fitting Bosch 14V 25A regulator (ref. Bosch 0190350049).But that regulator only held by one single screw on top of the generator, and since it was a bit too long, it had to be set askew... And, well, you know my OCD.

So i took a deep breath, a drill press, and drilled a 4.2mm hole in the generator body (making sure I wouldn't drill into a coil inside, obviously), which I proceeded to tap at 5x80 like the other one. Done! I then gave a lick of paint to the regulator, cut 3mm from its back stand, and now it ssits aligned with the generator. Much better!

As usual, since nothing is ever simple, while putting back together the fan assembly, torquing the nut at 6mkg, the expansible washer broke on me... Argh. Ordered a new one from VW Classic Parts (ref. 111119135), yet another week to wait... Damn, restoring these machines requires infinite patience!

...and reassembly!

To put everything back together, I ordered a set of stainless steel tinware screws identical to the original ones (mine weren't looking good). The cardboard "seal" between the generator and its stand is glued in place using Gasgacinch.I also give a coat of satin black on the coil (an actual, real blue Bosch one), the generator's pulley, and the oil pump plate (which I had forgotten, and already showed rust spots).

The coil also receives a sticker reproduction to make it look like an old 6V one... That'll make the trick!

After a bit more of fiddling... TADAAAAA!!

OK, almost there now... If the pain in my shoulder gives me some slack, this baby should run pretty soon!