Posted on 07/10/2020 at 16:30

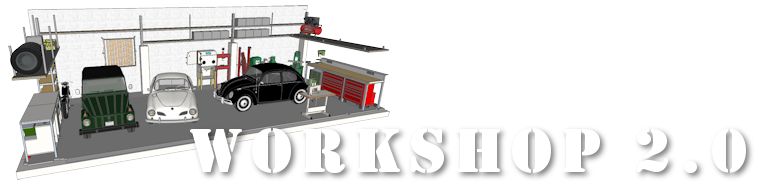

Workshop 2.0

I had mentioned it last January (actually, already teased about it in January 2018...), but here we are, I've got a new playground!

I had mentioned it last January (actually, already teased about it in January 2018...), but here we are, I've got a new playground!

A bit over two years ago, I moved to a new house, one of the main reasons being a hangar in the back garden... It's legit and on the land registry, but in a sore state, the steel structure being pretty rusty.

It took two years to tun it into a proper workshop. Authorizations, floods, heavy storms, suppliers delivery errors and delays, quarantine, Covid... Let's not go into details, but it's been hell to get stars to align! Well, at least it gave me ample time to refine my organization plans - I've have spent more time on Sketchup than I'm comfortable admitting.

So without further ado, here's the result! One large garage door that allows two vehicles facing out, ready to drive through, and an integrated walk-in door. And a large bay window to bring in light : A hoist on rail going all the way through the shop : To store stuff, shelves on the back wall, made to fit my Eurocrate format boxes, and on each side, two large "mezzanines" 70cm and 90cm deep, at a 2.10m height so I can comfortably walk below. And for the most curious of you wondering why the lower shelf doesn't extend all the way to the left : that's so that I can fit in a Westfalia Campervan one day! (that's the definition of wishful thinking right there) All my machines are not in yet, I still have to install all the electric outlets, and build a proper workbench, I'll slowly get to it step by step. And I use this time to sort out everything I've stored for like 25 years in my old garages... All in all, a bit over 50sqm (540sqft), leaving enough room to walk around the 2 cars behind the garage door, plus a "work zone" for a third car : So that's it! Full disclosure, that's a pretty big dream of mine made true right here...

A huge thank you to Gérald (and his two sons Kevin et Anthony!) for all the building work!

And big thanks to Bruno for lending me your tow bar to tow the cars between shops!

Now, I have to transfer all my tools/machines/parts from the old workshop... Maintenant, il n'y a plus qu'à rapatrier tous mes outils/machines/pièces... And find time to actually work on my projects!

Posted on 08/11/2022 at 17:20

Worshop : workbench 2.0

OK, my "Workshop 2.0" is pretty cool, but without a "workbench 2.0" to go with, it's difficult to work comfortably. I've been tinkering around until now on the top of my rolling tool chest, but now it's time to shift gears...

OK, my "Workshop 2.0" is pretty cool, but without a "workbench 2.0" to go with, it's difficult to work comfortably. I've been tinkering around until now on the top of my rolling tool chest, but now it's time to shift gears...

I already had built a workbench in my previous workshop : you can find all the details of its construction here ; it had even gotten a lick of paint later...

But the main difference is that back then the workbench was squeezed in between two walls, fixed on each side : in my new workshop I can not do the same as the walls are made out of insulated sandwich steel panels, which is not structurally sound. Here, the only points I can affix the workbench to are the workshop steel beam in the right corner... and the floor. The workbench structure will therefore have to be very sturdy, so as not to giggle around when I'm struggling with something in the vise....

So this time around, it won't be made out of wood, but out of steel : I'll built the structure out of 40x40mm and 80x40mm tubing (#overkill). I had some 40x40 left from the workshop building, so I tried to optimize my stock... Yes, I know, I have a severe case of undersizophobia.

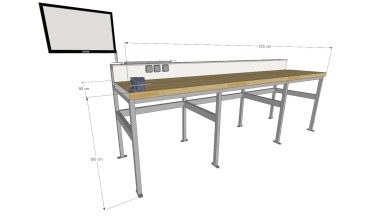

Design / Marking

Here we go : if it's not your first time here, you won't be surprised I started by a Sketchup design to find the best configuration : The outcome is 315cm long, 80cm deep, and 1m high, because I'm tall and tend to break my back on standard-height benches..I had initially planned on putting my rolling tool chest under the bench, but it would then have been too high, since I have a large shelf-like mezzanine above at 2m10. So I decided on putting the chest on the side, with a piece of countertop on it, to get a L-shaped workbench. OK, let's get to it!

I start by precisely marking, on the floor and the walls, where the workbench will fit, which I will use as a reference later (a laser level is perfect for this task). As the floor is not perfectly level, each of the 8 legs may have a slightly different length, so I'll build everything "on site" to ensure a square structure and a level top. Additional reason to build everything in place : the walls in that corner are not at a 90°, because of a shared wall with my neighbor, so this section of the workbench will not be at a square angle with the back wall, gonna have to adapt...

Structure

I then proceed to order the necessary steel from a wholesaler nearby, namely Durcomfer in Villeneuve Loubet : the 6m long 40x40 tubes cost me 36€TTC, while it would have taken me back 15/20€ per meter in a DIY superstore. Cheap, delivered the next day (for a 30€ fee), very welcoming people, I'll gladly do business with them again.To bolt them to the floor, each foot will be welded on a flat steel "sole" 40/8mm thick. Each "sol" is then bolted with two M8 70mm screws, into two Ø12mm steel pegs. That's a total of 16 M8 screws, I'm confident this bench is not going anywhere soon. #overkill4ever

That being said, full disclosure : I'm not going to win any competition with my welds, but they should hold!

Painting

I had initially planned on unbolting the structure from the ground to move it and finish my welds, as well as paint, behind it... In the end, I did nothing of the sort, so much for the 3 missing welds, the result is so much sturdier than I ever hoped it would be ; even when trying to jiggle it as hard as I can, it barely vibrates a millimeter. I even bought rubber pads to put between the legs and the wall to avoid any impact, but there is absolutely no risk it will ever happen.And my very OCD self will have to live with the fact the rear face of the structure is not painted (that one actually bothers me!)

The reason why I did not move the whole thing, is that the welds tend to put stress on the structure : if I had removed the screws from the floor, it would have been Hell to realign everything back in place... And this workbench is first and foremost a tool I wanna use as soon as possible, sue me for taking a shortcut.

The top of the back legs is left unpainted on purpose, as I will weld stubs on them to hold the back shelf.

Countertop

I ordered 2 counter tops from Leroy MErlin (french DIY store), 315cm long and 38mm thick, instead of the 58mm I originally wanted, just because it multiplied the cost by 3. I prepared the fixation by drilling 22 ø5mm holes in the structure, so I can screw the countertop from below.I just cut slightly the right end so as to adjust the top to the not-square wall, and I secured it with 70mm screws. Then I added the back shelf on top of the bench : I find it super useful to be able to store stuff right above the work area, plus it provides a vertical plan on which to put two dual electrical outlets... I can't remember where I salvaged the two lengths of perforated angle iron from, but it was maint to be, exactly the size I needed! Finally I add a piece of countertop on top of my rolling tool chest : the result is an L-shaped workbench, whilst keeping the tool chest mobile if required. I had calculated the workbench height based on the tool chest so they would end up aligned...

To keep the countertop piece in place on the chest, I routed grooves underneath that nicely fit over the tool chest flanges around its work area. It doesn't move at all, without any modification of the tool chest. The countertop is then cut to fit snugly around the steel beam.

And since I was left with another piece of countertop, I've put it on two sawhorses to get an additional, temporary/removable workbench (spoiler alert of the project I'm currently working on)...

Final Result

And... Tadaaaaaaaa!The outcome is really close to my initial Sketchup concept, and fulfills its purpose perfectly. There you go! I still gotta screw in the vise, and run electricity to the outlets, but I already actively use the bench!

Posted on 31/07/2024 at 15:35

Workshop organization : hardware trolley

In nearly 40 years of various DIY projects, I have accumulated a bunch of various storage boxes, for my screws, bolts, washers, dowels, terminals, etc. Obviously boxes of all sizes, making them difficult to organize and store, not mentioning find your way around easily.

It was time to find new...

AUER offers them in different sizes, with assortments of different compartments inside, and in standardized dimensions, stackable on my Euro standard storage bins of the same brand.

You can even customize them if you have a 3D printer, you can find specific compartments to print on Thingiverse and Printables.

This is free advertising, I'm not sponsored by them... But if by any chance AUER Packaging you're reading this...

I end up with ten of these organizers... And to be able to store them all, and find what I need easily, I made myself a custom-made trolley.

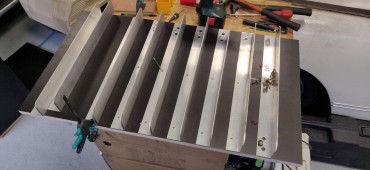

The structure will be in plywood, the organizers and trays being supported by aluminum angles screwed into the sides.

It was a bit boring to do: 36 aluminum angles, to cut then file to size, 54 corners to round, 108 holes to drill then mill and deburr... I was quite relieved when it was finished. For the plywood I use 18mm plywood for formwork (film-coated poplar from PointP ).

For the plywood I use 18mm plywood for formwork (film-coated poplar from PointP ).

The reason for this choice is that it is the cheapest plywood I could find, at €70 for a 250x125cm board (price at the time of purchase, it has increased since then)... You had to pay three times that in a DIY store.

The downside is that the boards are not perfect, as they are stored outside, so the edges can be a little delaminated and there is bot of little loss. But it is fine for the workshop and the price is unbeatable.

Cut with a plunge circular saw on a rail, and I screw everything together: I finished with 4 casters that had been lying around in a box for 15 years, and my new hardware trolley is ready!

Yeah, I know, it doesn't take much to make me happy right?

It was time to find new...

Organizers

I finally decided to invest a bit, and I replaced all my boxes (some of them I had since my teenage years!) with cases/organizers from AUER Packaging 40x30cm, featuring removable interior compartments. It's a beautiful product, very good quality, and even if it's not cheap, it's still much cheaper than an equivalent Sortimmo for example.AUER offers them in different sizes, with assortments of different compartments inside, and in standardized dimensions, stackable on my Euro standard storage bins of the same brand.

You can even customize them if you have a 3D printer, you can find specific compartments to print on Thingiverse and Printables.

This is free advertising, I'm not sponsored by them... But if by any chance AUER Packaging you're reading this...

I end up with ten of these organizers... And to be able to store them all, and find what I need easily, I made myself a custom-made trolley.

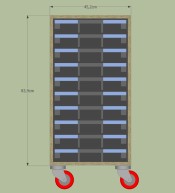

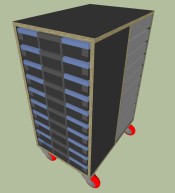

Design

I start with a design in Sketchup (no surprise if you've already been here): on the front my new organizers, and on the back as many flat trays of the same dimensions. And if necessary later, I can replace all or part of the flat tray with more organizers.The structure will be in plywood, the organizers and trays being supported by aluminum angles screwed into the sides.

Fabrication

The aluminum angles come from a stock of offcuts bought for cheap on LeBonCoin (the french Craig's List) : €40 for 14kg of ali angles, I have plenty left in stock! The same thing in a DIY store would have cost me an arm, a leg, and my son's soul: there are more than 12 linear meters in all!It was a bit boring to do: 36 aluminum angles, to cut then file to size, 54 corners to round, 108 holes to drill then mill and deburr... I was quite relieved when it was finished.

The reason for this choice is that it is the cheapest plywood I could find, at €70 for a 250x125cm board (price at the time of purchase, it has increased since then)... You had to pay three times that in a DIY store.

The downside is that the boards are not perfect, as they are stored outside, so the edges can be a little delaminated and there is bot of little loss. But it is fine for the workshop and the price is unbeatable.

Cut with a plunge circular saw on a rail, and I screw everything together: I finished with 4 casters that had been lying around in a box for 15 years, and my new hardware trolley is ready!

Resultat

This trolley slides along the workbench, at the same height, and by moving it I can easily access the milling machine behind. I use it all the time, and it's fantastic to finally find the bolts/washers/dowels you need right away - I only regret not having done it sooner!Yeah, I know, it doesn't take much to make me happy right?