Hardware trolley

In nearly 40 years of various DIY projects, I have accumulated a bunch of various storage boxes, for my screws, bolts, washers, dowels, terminals, etc. Obviously boxes of all sizes, making them difficult to organize and store, not mentioning find your way around easily.

It was time to find new...

Organizers

I finally decided to invest a bit, and I replaced all my boxes (some of them I had since my teenage years!) with cases/organizers from AUER Packaging 40x30cm, featuring removable interior compartments.

It's a beautiful product, very good quality, and even if it's not cheap, it's still much cheaper than an equivalent Sortimmo for example.

AUER offers them in different sizes, with assortments of different compartments inside, and in standardized dimensions, stackable on my Euro standard storage bins of the same brand.

You can even customize them if you have a 3D printer, you can find specific compartments to print on Thingiverse and Printables.

This is free advertising, I'm not sponsored by them... But if by any chance AUER Packaging you're reading this... 😉😁🙏

I end up with ten of these organizers... And to be able to store them all, and find what I need easily, I made myself a custom-made trolley.

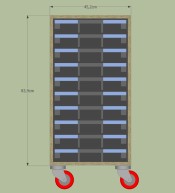

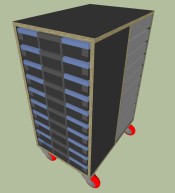

Design

I start with a design in Sketchup (no surprise if you've already been here): on the front my new organizers, and on the back as many flat trays of the same dimensions. And if necessary later, I can replace all or part of the flat tray with more organizers.

The structure will be in plywood, the organizers and trays being supported by aluminum angles screwed into the sides.

Fabrication

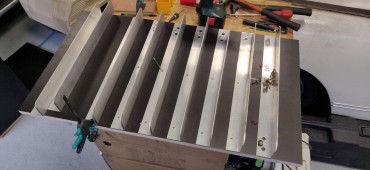

The aluminum angles come from a stock of offcuts bought for cheap on LeBonCoin (the french Craig's List) : €40 for 14kg of ali angles, I have plenty left in stock! The same thing in a DIY store would have cost me an arm, a leg, and my son's soul: there are more than 12 linear meters in all! 😉

It was a bit boring to do: 36 aluminum angles, to cut then file to size, 54 corners to round, 108 holes to drill then mill and deburr... I was quite relieved when it was finished.😉

For the plywood I use 18mm plywood for formwork (film-coated poplar from PointP ).

The reason for this choice is that it is the cheapest plywood I could find, at €70 for a 250x125cm board (price at the time of purchase, it has increased since then)... You had to pay three times that in a DIY store.

The downside is that the boards are not perfect, as they are stored outside, so the edges can be a little delaminated and there is bot of little loss. But it is fine for the workshop and the price is unbeatable.

Cut with a plunge circular saw on a rail, and I screw everything together:

I finished with 4 casters that had been lying around in a box for 15 years, and my new hardware trolley is ready!

Resultat

This trolley slides along the workbench, at the same height, and by moving it I can easily access the milling machine behind.

I use it all the time, and it's fantastic to finally find the bolts/washers/dowels you need right away - I only regret not having done it sooner!

Yeah, I know, it doesn't take much to make me happy right? 😉😁

Published on 31/07/2024 / 0 commentaires