Posted on 14/09/2011 at 19:25

Pacha : Log Book

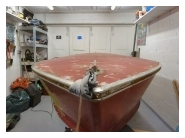

Quite a big update about the Albatross today : it's going forward, finally!

Quite a big update about the Albatross today : it's going forward, finally!To begin with, in early June I moved her to my workshop (which I recently refurbished) : I had to install a tow ball on Blue Toad, my VW Rabbit, with which I really have moved everything.

Anyway, the Pacha is finally in a place where I can take care of her, with light, room... Me likey! I've started working on the engine; not that many surprises for now : cylinders look clean, valves aren't seized.

In the other hand, the water inlet tube tube at the bottom of the block crumbled in pieces in my hand, rusted out. Same thing for the brass water tube that diverts part of the water water flow from main gallery towards valve chambers, totally destroyed by oxidization. Well, I'm not too concerned, these parts are available at Small Ford Spares...

But it looks like bits of metal went through the cooling circuit, which the water pump did not appreciate : its impeller lost several teeth in the battle. I'll have to take care of it, but again it shouldn't be an issue, all parts are available : impeller only, repair kit, or full pump exchange, everything's possible. I will also need a new flywheel, this one suffered from the extended stay in water.

I also got my hands on the spare engine Fred kept for me (thanks for your patience buddy!), I'm pretty sure I can make one good engine out of these two. Getting the engine out of the hull was easier than I thought. The small 100E block isn't that heavy... With the help of a friend (thanks David), it came out pretty easily.

The tricky part was to take the prop shaft out of the engine. A wedged assembly, corrosion, concretions on the shaft, et a big brass nut (which you must handle with care because fragile!), and you've got the perfect recipe for a headache.

Finally, by following BN's advices (from the OldSpeedBoats forum), a couple of clamps, a heavy hammer and some patience were enough to free the engine from the shaft.

The next challenge will be to take the rudder out, since its nut is not only rusted but as well pretty much inaccessible... And it must go, unless the prop shaft won't leave either.

In order to sandblast the hull, it also needs to be totally bare from any accessories. Everything must go! So I keep unscrewing stuff... Which is far from easy, since the 100 stainless steel screws had a galvanic reaction with the aluminium hull!

Each one of them is like "welded", and it's a renewed challenge every time to take them out. Any method is good : WD40, impact screwdriver, heat gun, hammer, pneumatic grinder... But at the end of the day, the one that gave the best results is using vise-grips, very tightly tighten on the inside part of the screw (once the nut is removed). Then, with a small back-and-fort movement, the screw gives in... But it take a solid 10mn per screw, and I count 60 of'em just from the aluminium rail around the hull! And you'd better not be claustrophobic : to get access to the front compartment, you need to crawl under the dashboard (being 6ft tall doesn't help, believe me), then slide head first into a 35cm (13.7") hole all the way to the waist ; my shoulders don't even fit in that hole, I need to pass one after the other, with razor-sharp edges all around, no room for my arms, no breathable air... Even though I'm not claustrophobic, I must admit that one night, alone at 1AM, stuck into that compartment, I wasn't feeling that comfortable.

By the way, I made a funny discovery : a series of numbers, handwritten with a lead pencil right below the rivets of the front compartment. I guess these are the riveting order, as written there by an Albatross Marine employee in 1957. And when I see how "easy" it is to get there, I wouldn't be surprised if I was the very first to see that since the boat was built. Touching, no?

So, that's where I've arrived! I often spend my evenings there ("I'm doing my Jethro", kudos to the one who gets the reference), therefore there's actual progress. I hope I'll get it bare by the end of the month, to get it sandblasted. To be continued soon!

1